As the demand for innovative and compact electronic devices continues to rise, the importance of flexible PCB fabrication has surged, making it a critical area for manufacturers and designers alike. According to a recent report from Research and Markets, the global market for flexible PCBs is projected to reach $26.8 billion by 2027, reflecting a compound annual growth rate (CAGR) of 14.7% from 2020. This impressive growth underscores the expanding applications of flexible PCBs in various sectors, including consumer electronics, automotive, and medical devices.

Dr. Emily Thompson, a leading expert in flexible electronics, highlights the revolutionary potential of this technology: “Flexible PCB fabrication not only allows for the creation of lighter and thinner devices but also enhances their durability and functionality in diverse environments.” As industries shift towards miniaturization and increased design flexibility, mastering the principles and techniques of flexible PCB fabrication will be essential for professionals looking to stay at the forefront of modern electronics production.

In this guide, we will explore the critical aspects and best practices of flexible PCB fabrication, providing insights that will empower engineers and designers to integrate this versatile technology into their electronic products effectively. Understanding the nuances of this advanced fabrication process will be crucial in harnessing its full potential and driving innovation in the ever-evolving landscape of electronics.

Flexible Printed Circuits (FPCs) have emerged as a pivotal innovation in modern electronics, offering unique advantages over traditional rigid circuit boards. Defined as a method that allows for the bending and shaping of electrical pathways, FPCs are essential for creating lightweight, compact, and reliable electronic devices. According to a recent market report, the global flexible printed circuit market is projected to reach USD 25.62 billion by 2025, driven by increased demand in sectors like consumer electronics, automotive, and medical devices. This signifies not only the technological shift but also the growing importance of flexibility in electronic design.

Understanding the significance of flexible PCBs goes beyond just their physical properties. They contribute to enhanced efficiency in design processes, enabling manufacturers to further miniaturize components while ensuring durability and performance. Moreover, flexible circuits can withstand dynamic movements, making them ideal for wearable technology and devices requiring complex shapes. A study highlights that the ability to integrate multiple functions within a single flexible circuit design reduces assembly time and costs, thus optimizing the production pipeline.

Tip 1: When designing for flexible PCBs, consider the bend radius. A tighter bend radius can lead to better performance but may create stress on the materials, potentially causing failure over time.

Tip 2: Utilize simulation software during the design phase to test the electrical and mechanical properties of your flexible circuit. This proactive approach helps identify issues before physical prototyping, saving time and resources.

This bar chart illustrates the market share of flexible PCBs across various applications in modern electronics as of 2025. The data indicates that smartphones dominate the market, while wearables and automotive applications also show significant demand.

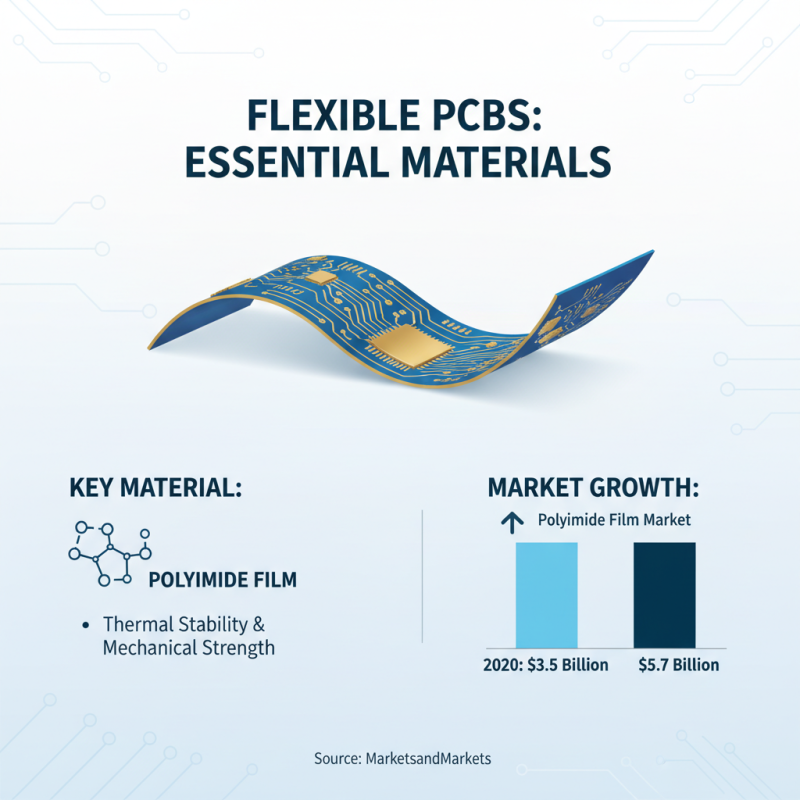

Flexible PCBs (Printed Circuit Boards) have become essential in modern electronics, enabling the design of lightweight and compact devices. The fabrication process of flexible PCBs involves a variety of specialized materials that contribute to their unique properties. One of the primary materials used is polyimide, known for its excellent thermal stability and mechanical strength. According to a report by MarketsandMarkets, the polyimide film market is projected to grow significantly from $3.5 billion in 2020 to $5.7 billion by 2025, indicating a rising demand for high-performance materials in flexible PCB applications.

In addition to polyimides, conductive inks and various types of copper foils are crucial in flexible PCB fabrication. Conductive inks, often printed using advanced technologies, allow for more versatile designs, particularly in applications requiring low-cost, rapid prototyping. Meanwhile, the choice of copper foil—be it rolled or electrodeposited—affects the conductivity and flexibility of the final product. A study by IDTechEx points out that the flexible electronics market, which prominently features flexible PCBs, is expected to reach $50 billion by 2030, emphasizing the growing importance of advanced materials in meeting the industry's demands. As manufacturers innovate with these materials, the capabilities of flexible PCBs continue to expand, allowing for their integration into an ever-increasing range of applications.

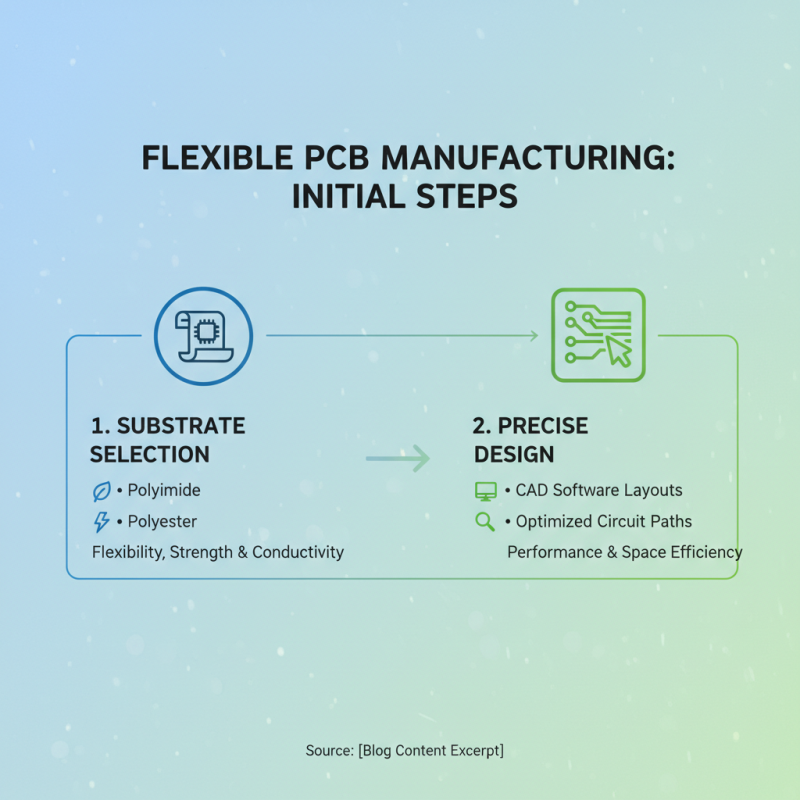

Flexible PCB manufacturing is a multifaceted process that requires meticulous attention to detail and a thorough understanding of materials and techniques. The first step involves selecting high-quality substrates that provide the desired balance of flexibility, strength, and conductivity. Common choices include polyimide and polyester, which are both lightweight and resistant to extreme conditions. Following substrate selection, a precise design is crucial. This includes creating detailed layouts using CAD software, ensuring that all circuit paths are optimized for performance and minimal space consumption.

Once the design is finalized, the fabrication process begins with the application of a copper layer onto the substrate through processes like etching. This step is critical as it determines the conductive pathways for the electronic signals. After etching, additional layers may be added to enhance functionality, such as solder mask application and surface finish. Testing is also an integral part of manufacturing to identify any defects early in the process. Finally, the PCB is cut to size, and finishing touches are applied, including the addition of components. Effective management of each step ensures that the resulting flexible PCBs meet the stringent requirements of modern electronic applications, enabling innovations in various industries.

Flexible PCB fabrication presents unique challenges that can hinder the efficiency and quality of the final product. One significant issue is the material choice; flexible PCBs require specialized substrates that can withstand bending and stretching without compromising performance. To overcome this challenge, it is essential to select high-quality, proven materials that have been tested for durability under various conditions. Furthermore, ensuring that the manufacturing process adheres to precise specifications can prevent common failures associated with poor material performance.

Another challenge in flexible PCB fabrication is the intricate design and layout required to accommodate the flexibility without sacrificing functionality. Complex paths must be meticulously designed, often leading to increased chances of errors during production. To mitigate this, utilizing advanced design software that supports flexible PCB design can dramatically reduce the risk of mistakes.

Tips: Regularly inspecting prototypes during the fabrication process can provide valuable insights into potential problems before mass production. By incorporating rigorous testing and validation stages, manufacturers can identify areas for improvement and ensure that the final product meets both performance and reliability standards. Additionally, staying updated with the latest technologies and methods in flexible PCB fabrication can lead to enhanced efficiency and reduced manufacturing costs.

The future of flexible printed circuit board (PCB) technology is poised for remarkable advancements, driven by the rising demand for miniaturization and flexibility in electronic devices. As industries increasingly embrace wearable technology, Internet of Things (IoT) devices, and smart textiles, flexible PCBs present a unique solution that adapts to varying shapes and sizes. This adaptability not only allows for the creation of lighter and thinner devices but also facilitates innovative design possibilities that were previously unattainable with traditional rigid circuit boards.

Emerging trends in flexible PCB applications indicate a growing interest in multi-layer structures and integrated functionalities. Manufacturers are exploring advanced materials, such as conductive inks and high-temperature laminates, which enhance performance and reliability. Furthermore, advancements in surface mount technology and laser processing techniques are improving precision in fabrication, paving the way for more complex designs. As these technologies evolve, flexible PCBs are expected to play a crucial role in sectors like healthcare, automotive, and consumer electronics, significantly impacting how devices are designed and utilized in everyday life.