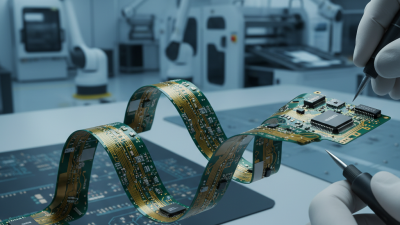

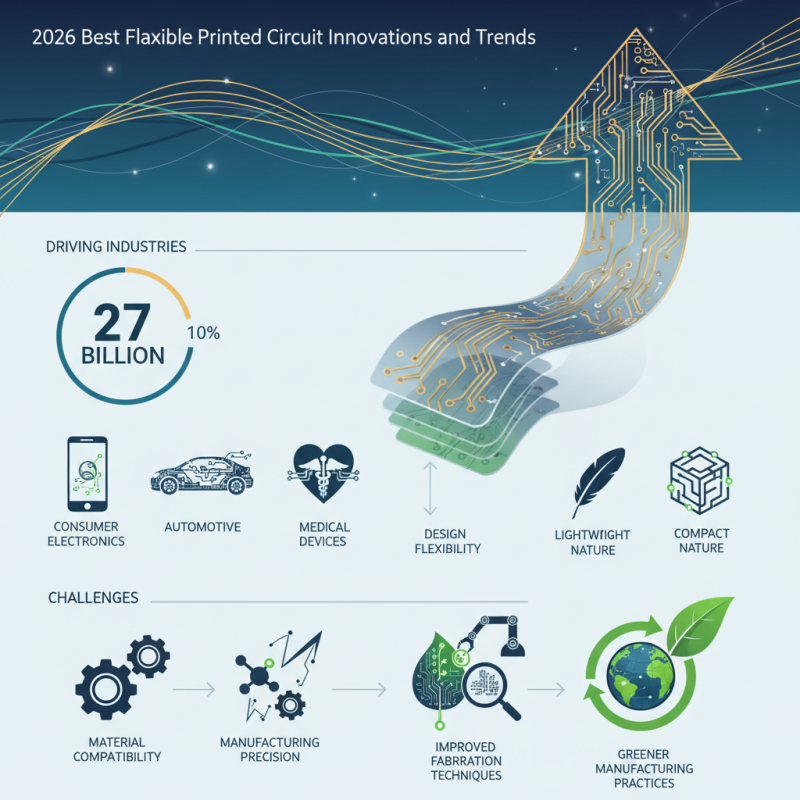

The flexible printed circuit (FPC) industry is experiencing remarkable growth. According to a recent market report, the global FPC market is projected to reach $27 billion by 2026. This reflects a compound annual growth rate of 10%. The demand is driven by advancements in consumer electronics, automotive, and medical devices.

FPCs are shaping various applications, offering unparalleled design flexibility. Their lightweight and compact nature allows for intricate designs that traditional circuits cannot achieve. For instance, smartphones and tablets utilize these circuits to maximize available space. However, challenges remain, such as material compatibility and manufacturing precision.

Recent innovations showcase eco-friendly materials and improved fabrication techniques. Companies are investing in research to address these issues. The race for innovation continues, but the industry must also reflect on sustainability. The trend towards greener manufacturing practices is essential for long-term success in the FPC sector.

The future of flexible printed circuits looks promising in 2026. Emerging technologies are pushing boundaries. One significant trend is the integration of nanomaterials. These materials enhance conductivity while reducing weight. This innovation can be crucial for wearables and compact devices.

3D printing is also making waves. It allows for customized designs and rapid prototyping. This flexibility can transform production processes. However, challenges remain, such as ensuring durability. Engineers need to rethink traditional approaches to meet new demands.

Moreover, the rise of Internet of Things (IoT) devices drives innovation. As the number of connected devices grows, so does the need for efficient circuits. Designers must create circuits that can withstand various environments. This may require more research and development. Balancing performance and cost is essential. The evolution of flexible printed circuits continues to present both challenges and exciting possibilities.

The future of flexible printed circuits (FPCs) is shaped by several key trends. One significant trend is the growing demand for miniaturization. Devices are getting smaller, and circuits must adapt. Industries are pushing for thinner, lighter designs. This creates challenges for manufacturers. They must find ways to maintain performance while reducing size.

Another important aspect is sustainability. More companies are focusing on eco-friendly materials and production processes. Reducing waste is a priority. Innovations in biodegradable materials are emerging. However, finding the right balance between performance and sustainability is not straightforward.

Advancements in manufacturing techniques are also notable. Techniques like 3D printing and laser cutting are becoming more common. These methods improve precision and reduce costs. Yet, they come with a steep learning curve for some manufacturers. Continuous exploration is necessary to fully leverage these technologies. The path forward holds great promise, but it requires careful consideration and adaptation.

| Trend | Description | Impact Level | Expected Adoption Rate (by 2026) |

|---|---|---|---|

| Miniaturization | Advancements in the production of smaller and thinner circuits to accommodate compact electronic devices. | High | 85% |

| Eco-friendly Materials | Increased use of biodegradable and recyclable materials in circuit production. | Medium | 60% |

| Wearable Technology Integration | Enhanced flexible circuits designed specifically for wearable devices and health monitoring. | High | 75% |

| 3D Printing of Circuits | Utilizing 3D printing technology to produce flexible circuits on demand. | Medium | 50% |

| Increased Thermal Management | Innovations focused on improving heat dissipation and management in flexible circuits. | High | 70% |

The field of flexible printed circuits is undergoing rapid evolution, especially in materials. Innovations focus on enhancing flexibility without compromising durability. Recent advancements include the development of new polymers. These materials offer improved stretchability and resilience, crucial for modern applications.

Engineers are experimenting with hybrid materials that combine different properties. For instance, integrating conductive inks with flexible substrates creates circuits that are both lightweight and robust. This approach allows for intricate designs while maintaining performance under stress. However, challenges like manufacturing consistency still exist. Ensuring quality across batches remains a significant hurdle.

Sustainability is also a growing concern. Some materials are derived from renewable resources, yet questions about their long-term reliability linger. Balancing environmental impact with product performance demands innovative thinking. As the industry pushes forward, continuous evaluation of material choices will be essential for real progress. While the future looks promising, there's still a journey ahead.

Flexible printed circuits (FPCs) have found extensive applications across various industries. The automotive sector, for example, increasingly relies on these circuits to enhance the functionality of electronic systems. Reports indicate that 70% of new vehicles incorporate FPCs for features like navigation and driver assistance. These circuits allow for lightweight designs, which translate to better fuel efficiency.

The healthcare industry is another area witnessing a surge in FPC use. Wearable health monitoring devices benefit from the flexibility and compactness of these circuits. According to a market analysis, the global demand for flexible printed circuits in healthcare is expected to grow by 15% annually. However, some challenges remain. Many manufacturers grapple with quality control during the production process.

Moreover, consumer electronics is a significant market for FPCs. Devices like smartphones and tablets integrate these circuits for enhanced performance. A staggering 90% of portable electronics now employ flexible printed circuits. This adaptation facilitates intricate designs that traditional circuits cannot achieve. Nevertheless, companies must continually adapt to rapidly changing consumer preferences and innovations, which sometimes outpace current manufacturing capabilities.

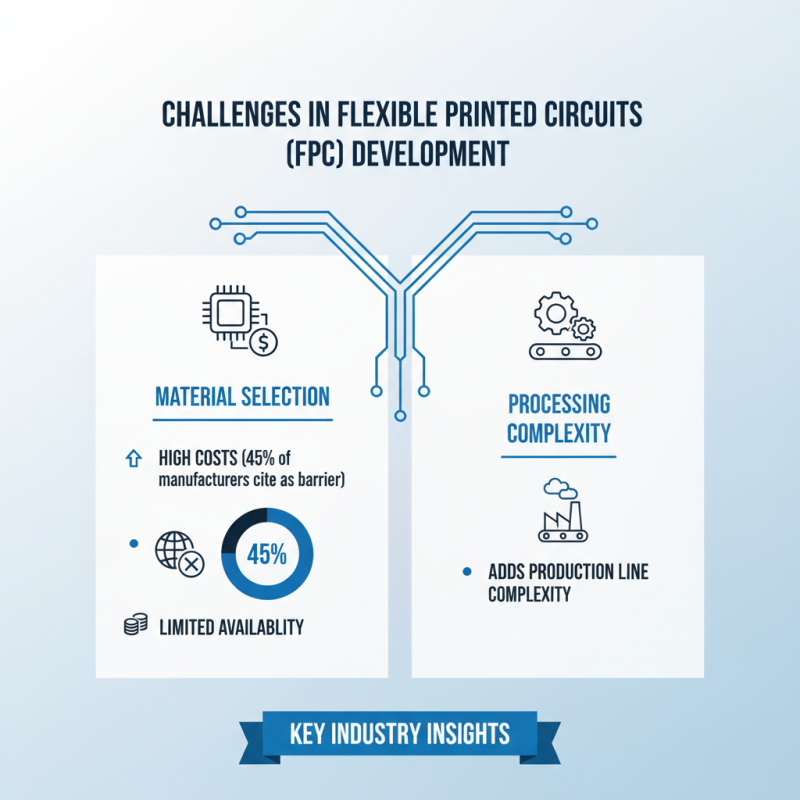

The development of flexible printed circuits (FPCs) faces several challenges. One main issue is the material selection process. High-performance materials can be costly and may not be widely available. According to recent industry reports, 45% of manufacturers cite material costs as a significant barrier. Additionally, the processing of these materials can add complexity to production lines.

Manufacturers often struggle with adhering to the tight tolerances required for FPCs. As devices become smaller, the need for precision increases. A report highlighted that nearly 30% of production defects arise from poor alignment during the manufacturing process. Improving machinery calibration is essential but requires investment and training.

Another challenge is the limited lifespan of flexible circuits. While flexible designs offer advantages, their durability under stress is questioned. Studies indicate that nearly 25% of flexible circuits fail during testing for reliability. Regular feedback loops and ongoing testing protocols need to be established. Continuous assessment of material performance can guide future innovations.