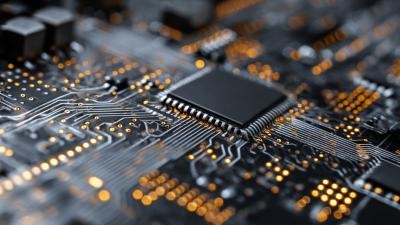

In the rapidly evolving landscape of modern electronics, the adoption of flexible printed circuits (FPCs) has become a game changer. Leading industry expert Dr. Emily Chen, a renowned specialist in circuit design, states, “Flexible printed circuits are revolutionizing not just how devices are built, but how they function and interact with users.” This innovative technology offers a multitude of benefits that cater to the increasing demand for compact and lightweight electronic components, facilitating the creation of more sophisticated, high-performance devices.

From smartphones and wearable technology to medical equipment and automotive applications, flexible printed circuits play a pivotal role in enhancing device functionality while optimizing space and resources. Their ability to bend, twist, and stretch without compromising performance makes them ideal for applications where traditional rigid circuits would fall short. As the electronics industry continues to push boundaries, understanding the top 10 benefits of using flexible printed circuits is crucial for manufacturers looking to stay competitive and meet the diverse needs of today's consumers.

Flexible printed circuits (FPCs) hold a significant advantage in modern electronics due to their compact design capabilities. As devices become smaller and more intricate, FPCs offer the flexibility needed to fit into tight spaces without sacrificing performance. Unlike traditional rigid circuits, FPCs can be bent, folded, or twisted, allowing engineers to optimize their layouts and make the most of available real estate within devices. This adaptability is essential for creating innovative designs across various applications, from smartphones to medical devices, where space is often at a premium.

Moreover, the lightweight nature of flexible printed circuits plays a crucial role in enhancing the overall efficiency of electronic products. By minimizing weight, manufacturers can develop lighter devices, which not only improve portability but also reduce energy consumption. The reduced dimensions and weight of FPCs contribute to a more streamlined assembly process, making it easier to incorporate multiple functionalities into a single unit. This leads to the development of advanced electronics that are not only compact but also more user-friendly, allowing for greater integration of features without compromising design or functionality.

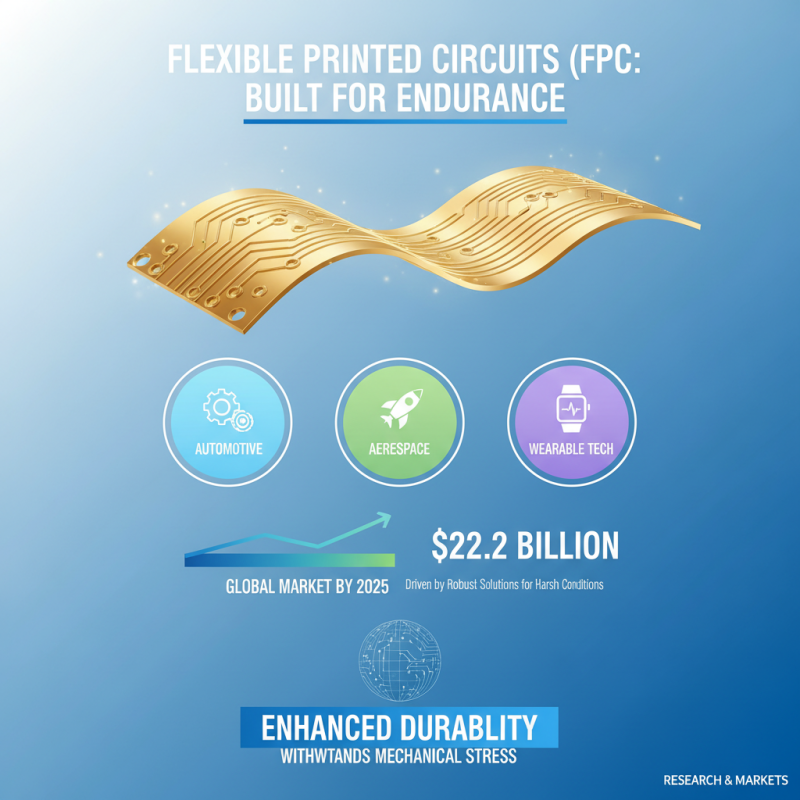

In the realm of modern electronics, flexible printed circuits (FPCs) stand out for their enhanced durability, particularly in challenging environments. FPCs are designed to withstand significant mechanical stress, making them ideal for applications in automotive, aerospace, and wearable technology. According to a report by Research and Markets, the global flexible printed circuit market is expected to reach $22.2 billion by 2025, driven in part by the growing demand for robust electronic solutions that can endure harsh conditions.

These circuits exhibit superior resilience against temperature fluctuations, humidity, and vibration, which is critical in industries like aerospace where components are regularly exposed to extreme conditions. The ability of FPCs to bend and fit into compact spaces without compromising performance adds to their appeal. Notably, the integration of advanced materials in FPC manufacturing contributes to their longevity and reliability, reducing the need for frequent replacements—a vital consideration in cost-sensitive projects.

Tips: When selecting flexible printed circuits for your projects, consider the environmental factors your electronics will face. Additionally, always consult with manufacturers to understand the specific material properties and certifications of the FPCs you plan to use, ensuring they meet your durability requirements. Finally, proper installation techniques can further enhance the lifespan and performance of these circuits, making it essential to follow best practices during assembly.

Flexible printed circuits (FPCs) offer significant cost-effectiveness in manufacturing and assembly compared to traditional rigid circuit boards. One of the primary reasons for this advantage lies in their ability to be produced using automated processes that streamline production. This automation not only reduces labor costs but also minimizes the likelihood of human error, leading to a more efficient manufacturing cycle. The lightweight nature of flexible circuits also means that less material is required, further decreasing overall production costs.

In addition to lower manufacturing costs, flexible printed circuits facilitate easier assembly and integration into electronic devices. Their versatility allows for them to be designed in various shapes and sizes, enabling manufacturers to create compact and lightweight products without compromising functionality. This can lead to savings in shipping and raw material expenses.

Moreover, the reduced number of components required—thanks to the all-in-one nature of FPCs—can lead to a faster assembly process, ultimately reducing time-to-market for new electronic devices. This combination of streamlined production and assembly processes highlights how FPCs not only cut costs but also improve the overall efficiency of the electronic manufacturing industry.

Flexible printed circuits (FPCs) are revolutionizing the landscape of modern electronics, particularly through their enhanced thermal management capabilities. The unique structure of FPCs allows for efficient heat dissipation, which is crucial for maintaining the reliability and performance of electronic components. According to a report by the IPC (Institute of Printed Circuits), inadequate thermal management is one of the leading causes of failure in electronic devices, impacting both longevity and functionality. FPCs can significantly reduce thermal resistance compared to traditional circuit boards, enabling better heat distribution across components.

Recent industry data highlights that flexible circuits can improve thermal performance by up to 30% through design optimizations that incorporate thermal vias and greater surface area exposure. This is particularly beneficial in densely packed devices where space is at a premium. Engineers have reported that the innovative layering techniques and materials used in FPCs facilitate effective thermal transfer, even in high-temperature conditions. As consumer demand for compact, high-performance electronics grows, the ability to manage heat efficiently is becoming a critical factor in design decisions. Thus, FPCs not only address thermal challenges effectively but also contribute to the overall reliability of modern electronic devices.

| Benefit | Description | Impact on Thermal Management |

|---|---|---|

| Compact Design | Flexible printed circuits enable smaller and more efficient designs, reducing overall size of devices. | Improved heat dissipation due to optimized component placement. |

| Weight Reduction | Use of lightweight materials reduces the overall weight of the electronic assembly. | Lower thermal mass contributes to faster heat transfer. |

| Enhanced Thermal Performance | Flexible circuits can be designed to better manage heat across components. | Allows for better thermal distribution and management strategies. |

| Reduced Hotspots | Flexible form factors can mitigate overheating in specific areas. | Improves longevity and reliability of the electronic components. |

| Improved Routing Options | Flexible circuits allow for innovative routing of power and signals. | Facilitates efficient thermal pathways. |

| Higher Signal Integrity | Minimized distance between components reduces signal degradation. | Helps maintain performance in thermally sensitive applications. |

| Enhanced Durability | Flexible materials offer resistance to mechanical stress and fatigue. | Supports thermal cycling without degradation. |

| Lower Manufacturing Costs | Streamlined processes reduce assembly and materials costs. | Cost-effective thermal management solutions. |

| Elimination of Interconnects | Flexible circuits reduce the need for discrete interconnects. | Minimizes potential thermal bottlenecks. |

| Environmental Resistance | Materials used in flexible circuits can be designed to withstand harsh environments. | Protects sensitive components from thermal stresses. |

Flexible printed circuits (FPCs) play a crucial role in the evolution of modern electronics, particularly in facilitating the integration of advanced technologies in devices. These circuits allow for a high degree of design flexibility, enabling manufacturers to create compact and lightweight solutions that can fit into various shapes and sizes, essential for innovative product development. This adaptability is particularly beneficial for incorporating features like touch screens, sensors, and wireless communication, all of which are vital for today's sophisticated electronics.

Tips for designers:

Furthermore, the flexibility of these circuits not only accommodates shrinking product dimensions but also enhances thermal management and signal integrity. By leveraging advanced manufacturing techniques, designers can achieve intricate patterns and connections that support high-speed operations and multi-functional capabilities. Embracing FPC technology can therefore lead to revolutionary advancements in electronics, creating devices that meet the evolving demands of consumers and industries alike.