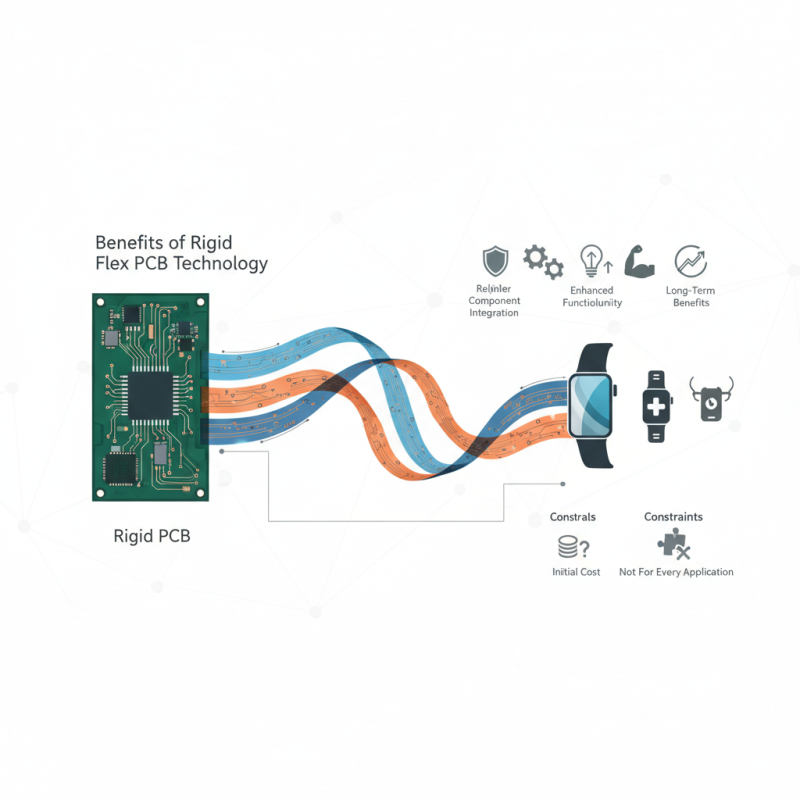

In the realm of modern electronics, PCB rigid flex technology stands out as a transformative solution. This innovative approach combines the benefits of both rigid and flexible printed circuit boards. It enables designs that were once deemed impossible. Engineers are embracing this technology to create compact, lightweight devices with enhanced functionality.

Rigid flex PCBs allow for tighter integration of components. This leads to a more reliable performance in diverse conditions. For instance, wearables and compact medical devices have significantly benefited from this fusion. The ability to bend without breaking is crucial for these applications. However, the manufacturing process can present challenges, requiring careful planning.

As we delve into the advantages of rigid flex technology, it's important to recognize a few constraints. While it enhances design, it may not suit every application. Some users may face higher initial costs, prompting a careful evaluation. Yet, the long-term benefits often outweigh these drawbacks, making PCB rigid flex a compelling choice in the electronic landscape.

Rigid flex PCB technology is gaining traction in modern electronics. Many industries benefit from its unique design capabilities. According to a recent market report, the rigid flex PCB market is projected to grow at a CAGR of 9.4% from 2021 to 2026. This growth reflects rising demand for lightweight, space-saving solutions.

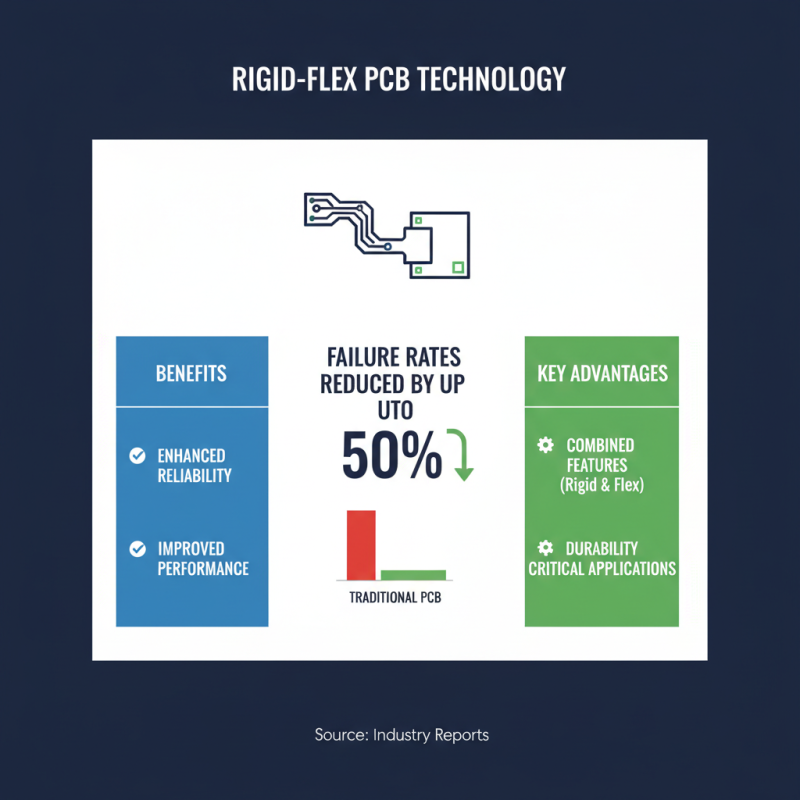

One significant advantage of rigid flex PCBs is their ability to withstand harsh conditions. They perform well in extreme temperatures and vibrations. A report from IPC highlights that these boards reduce the risk of failures, which can be costly. In aerospace and medical equipment, reliability is crucial. Engineers often grapple with the challenges of balancing size and durability.

Another notable benefit is the reduction of assembly time. Fewer connections are needed, which simplifies manufacturing processes. A survey by iSuppli indicates that companies save an average of 15% on production costs when using rigid flex designs. However, this technology is not without its obstacles. Some manufacturers struggle with the initial investment and complexity of production. As the demand for intricate electronic designs increases, engineers must adapt. The future will require innovative solutions to optimize rigid flex applications effectively.

Rigid flex PCB technology has revolutionized the design of electronic devices, particularly in miniaturization. This advancement allows for a combination of rigid and flexible circuit boards. As a result, engineers can design compact devices without compromising functionality. According to a market report by IDTechEx, the rigid flex PCB market is expected to grow at a rate of 12% annually over the next five years. This significant growth indicates the rising demand for miniaturized electronics.

The impact of rigid flex PCBs on device size is profound. They enable manufacturers to reduce space by integrating complex circuits into a smaller footprint. For instance, medical devices benefiting from this technology are now smaller and lighter, improving portability. This shift allows users to experience advanced functionality in a compressed form. However, this miniaturization comes with challenges. Designers must carefully consider thermal management and signal integrity as components shrink.

These challenges highlight a need for continual innovation. Engineers are pushed to enhance design strategies to meet the demands of smaller devices. The growth in the flexible electronics sector shows that while miniaturization is key, balancing performance and reliability remains critical. The future of Rigid flex PCBs is bright, but careful thought is needed to navigate its complexities.

Rigid flex PCB technology offers significant advantages in cost efficiency, especially in high-volume production scenarios. According to a recent industry report, using rigid flex PCBs can reduce manufacturing costs by nearly 30% compared to traditional PCBs. This is largely due to their ability to combine multiple components into a single unit. Fewer components mean lower assembly costs and reduced labor.

Additionally, rigid flex PCBs eliminate the need for connectors. This simplification often leads to a more reliable product. Reliability is key, as the electronics market increasingly demands durability in compact designs. However, these benefits may come with a higher initial investment in the design phase. Some companies struggle to adapt to this upfront cost. This can lead to hesitation in adopting rigid flex technology despite its long-term savings.

Furthermore, research indicates that optimizing rigid flex designs can yield even greater cost reductions. Designers must find the right balance between flexibility and robustness. This challenge requires careful planning and resource allocation. The investment in time and resources is essential for achieving full potential. Embracing these improvements in manufacturing processes could reshape the future of electronics.

| Benefit | Description | Cost Efficiency (% Reduction) | High-Volume Production Suitability |

|---|---|---|---|

| Space Savings | Rigid flex PCBs allow for more compact designs, reducing the size of the final product. | 20% | Highly suitable |

| Weight Reduction | They help decrease the overall weight of electronic devices, which is critical for portable applications. | 15% | Highly suitable |

| Increased Durability | Rigid flex PCBs offer better resistance to shock and vibration compared to traditional PCBs. | 10% | Suitable |

| Lower Assembly Costs | Fewer individual components mean lower assembly costs in high-volume production. | 25% | Highly suitable |

| Reduced Risk of Failure | Fewer interconnections lead to a decreased risk of failures in the final product. | 18% | Suitable |

Rigid flex PCB technology enhances reliability and performance in modern electronics. These PCBs combine the best features of rigid and flex circuits. According to industry reports, they reduce failure rates by up to 50%. This reduction is critical in applications where durability is vital.

The flexibility of a rigid flex PCB allows for complex designs. They can endure mechanical stress better than standard circuits. Various studies indicate they maintain integrity even under temperature changes and vibrations. This characteristic is vital in sectors like aerospace and medical devices, where performance is non-negotiable.

However, not all manufacturers fully understand the technology. There can be issues with manufacturing precision. Misalignment during production can lead to decreased performance. These shortcomings remind us that while rigid flex PCBs offer many advantages, careful consideration is essential for optimal results.

Rigid flex PCBs are transforming the landscape of IoT and wearable technology. These circuits combine the benefits of rigid and flexible boards. Their unique design allows for complex layouts, fitting various shapes in compact spaces. For wearables, comfort is key. Rigid flex PCBs can bend without compromising performance. This flexibility enhances user experience in devices like smartwatches and fitness trackers.

In the IoT sector, these PCBs enable sleek and efficient designs. Smart home devices increasingly rely on rigid flex technology. They reduce the overall size while improving functionality. Sensors can be seamlessly integrated into various surfaces. However, manufacturing challenges remain. The creation process can be intricate. It's vital to ensure quality throughout production, which may require additional oversight.

As manufacturers explore this technology, the learning curve can be steep. Misalignment and connectivity issues may crop up. These hurdles are not insurmountable. Continuous innovation is necessary. Designers and engineers must collaborate closely. This partnership is crucial to harness the full potential of rigid flex PCBs. The journey continues as we push boundaries in technology.