In the rapidly evolving landscape of modern electronic designs, the utilization of rigid PCBs (Printed Circuit Boards) has emerged as a cornerstone in the creation of advanced electronic devices. According to a report by Research and Markets, the global PCB market is projected to reach $100 billion by 2025, underscoring the increasing significance of rigid PCBs in architecture that demands reliability and efficiency. Rigid PCBs, known for their robustness and mechanical durability, provide a stable platform for a variety of components, enabling intricate circuitry to be compactly arranged while minimizing signal interference.

Moreover, the engineering advantages of rigid PCBs align well with the trends toward miniaturization and higher performance in electronics. IMARC Group asserts that the demand for rigid PCBs is driven by key sectors such as automotive, telecommunications, and consumer electronics, which increasingly require sophisticated circuit structures to support modern functionalities like IoT and 5G technology. As electronic designs continue to push the boundaries of innovation, understanding the myriad benefits of employing rigid PCBs is essential for engineers and designers aiming to stay at the forefront of the industry.

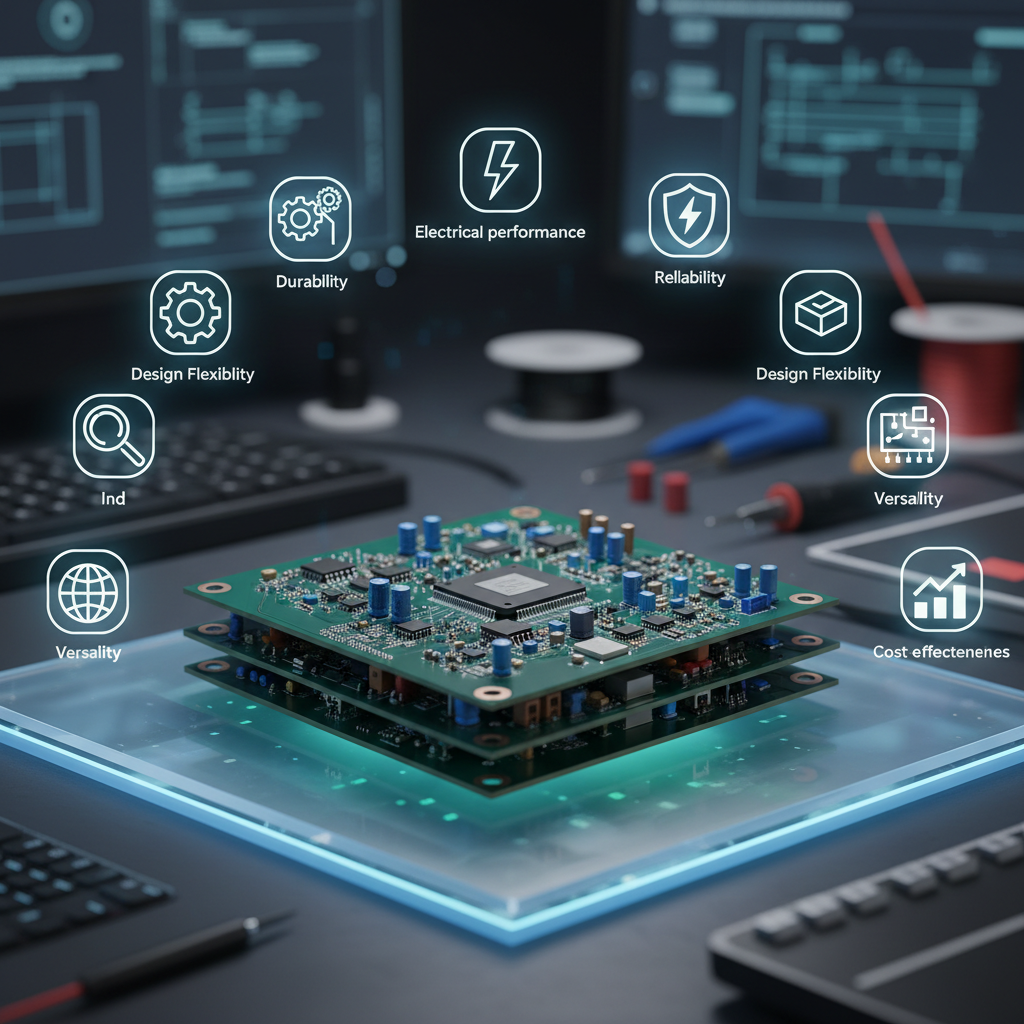

Rigid PCBs (Printed Circuit Boards) offer a myriad of advantages in high-density electronic applications, making them a preferred choice for modern electronic designs. One of the primary benefits is their robust physical structure, which supports intricate circuitry and provides a stable platform for advanced components. This rigidity ensures that the components remain firmly in place, reducing the risk of mechanical failures and enhancing the longevity of the devices, particularly in demanding environments.

Moreover, rigid PCBs facilitate efficient thermal management, an essential factor in high-density applications where components generate significant heat. The use of materials with excellent thermal conductivity helps dissipate heat effectively, preventing overheating and improving overall system performance. Additionally, their ability to integrate multiple layers allows for compact designs, accommodating more functionalities within constrained spaces without sacrificing reliability. This combination of durability and efficient thermal performance makes rigid PCBs an indispensable solution for today's sophisticated electronic systems.

This bar chart illustrates the top 10 benefits of using rigid printed circuit boards (PCBs) in modern electronic designs. Each benefit is scored based on its importance in high-density electronic applications, highlighting why rigid PCBs are favored in many industries.

The electronics industry is witnessing a significant transformation, largely due to the miniaturization of printed circuit boards (PCBs), which enhances efficiency and reliability across various sectors. One of the standout features of rigid PCBs is their improved thermal management capabilities. As electronic devices become smaller and more complex, the need for effective heat dissipation becomes critical. Rigid PCBs are designed to better withstand high temperatures and manage thermal energy, thereby prolonging the lifecycle of electronic components and preventing potential failures.

Furthermore, the market for rigid flexible PCBs is experiencing substantial growth, projected to reach approximately USD 3.62 billion in China by 2024, with an anticipated compound annual growth rate (CAGR) of 12.4%. This growth can be attributed to the increasing demand for high-performance electronics in industries such as automotive, where the market size is forecasted to hit USD 18.14 billion by 2034. The integration of advanced thermal management features in rigid PCBs not only enhances the performance of these devices but also aligns with the ongoing trends of technological innovation and efficiency improvements, thereby setting the stage for future advancements in the electronics sector.

Rigid PCBs, or printed circuit boards, offer significant advantages in modern electronic designs, particularly when it comes to signal integrity. The robust construction of rigid PCBs ensures that the pathways for electrical signals remain stable and free from distortion, which is essential for high-speed applications. Unlike flexible PCBs, rigid boards do not bend or flex, minimizing the risk of micro-cracking in traces and solder joints. This stability not only enhances the longevity of electronic devices but also contributes to consistent performance across varying environmental conditions.

Another important aspect of rigid PCBs is their excellent thermal management capabilities. The solid structure allows for effective heat dissipation, which is critical in high-performance electronics. By maintaining optimal operating temperatures, rigid PCBs reduce the likelihood of signal degradation that can occur due to overheating. This feature, combined with precise manufacturing techniques that allow for tight tolerances, leads to improved signal quality and reduced electromagnetic interference. As a result, rigid PCBs not only facilitate the functionality of complex electronic systems but also elevate their reliability and efficiency.

Rigid PCBs (Printed Circuit Boards) have become a staple in modern electronic designs due to their enhanced reliability and longevity. Statistics indicate that the global automotive PCB market is expected to grow significantly, increasing from $9.15 billion in 2023 to $15.1 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.9%. This growing demand can largely be attributed to the superior durability and performance of rigid PCBs, which are crucial in high-stress applications such as automotive and industrial electronics.

In the face of rapid technological advancements, particularly with the rise of AI, renewable energy, and high-speed communication, the implementation of rigid PCBs is essential. These PCBs offer a robust solution that can withstand extreme conditions, ensuring longer lifespan and reducing the frequency of replacements. As various sectors strive for efficiency and reliability, the ability of rigid PCBs to support complex designs and high-layer counts—some reaching up to 68 layers—makes them invaluable in achieving the next generation of electronic devices, thereby driving the industry’s growth forward.

The cost-effectiveness of rigid printed circuit boards (PCBs) plays a pivotal role in their widespread adoption across various electronic designs. With the PCB industry projected to grow significantly, reaching an estimated USD 18.14 billion in the automotive sector by 2034, the demand for cost-efficient manufacturing processes is on the rise. Investment in advanced fabrication technologies not only enhances production efficiency but also reduces expenses associated with materials and labor. As manufacturers adopt mass production techniques, the economies of scale allow for lower per-unit costs, making rigid PCBs an attractive option for companies aiming to optimize their budgets.

Additionally, the push towards the miniaturization of electronic components has bolstered the necessity for reliable and compact designs. As outlined in industry forecasts, the PCB market outlook from 2025 to 2027 is optimistic, driven largely by innovations that prioritize both performance and affordability. The integration of AI-driven design and sustainable manufacturing practices further enhances the cost-effectiveness of rigid PCBs, enabling manufacturers to meet growing demands while managing expenses. This creates a win-win scenario where the efficiency and reliability of critical applications are not compromised, ensuring that the electronics industry continues to thrive.

| Benefit | Description | Cost Impact (%) | Production Efficiency |

|---|---|---|---|

| Durability | Rigid PCBs are robust and can handle stress better than flexible options. | 5% | High efficiency due to fewer breakages. |

| Cost-Effectiveness | Lower production costs in large volumes compared to other types. | 15% | Streamlined processes save time and resources. |

| Design Versatility | Supports various designs and layouts making it adaptable. | 8% | Easily accommodates complex circuitry. |

| Thermal Management | Efficient heat dissipation for enhanced performance. | 7% | Maintains optimal working temperatures for components. |

| Electrical Performance | High reliability and signal integrity for better performance. | 12% | Reduces issues like crosstalk and interference. |

| Mass Production Capability | Easily scalable for high-volume production needs. | 20% | Rapid production turnaround times. |

| Maintenance and Repair | Simplified for repair due to access to components. | 3% | Less downtime for maintenance and upgrades. |

| Environmental Stability | Better resistance to environmental factors like moisture. | 6% | Longer lifespan under various conditions. |

| Cost Predictability | Stable pricing for materials and processes. | 4% | Easier budgeting for projects. |

| Quality Assurance | Stringent quality control processes lead to consistency. | 10% | Reliability in performance results in fewer failures. |