The demand for flexible PCB fabrication is soaring in various industries. According to a report by IDTechEx, the flexible electronics market is projected to reach $76 billion by 2025. This rapid growth is driven by the increasing need for lightweight and compact electronic devices. Flex PCBs find applications in smartphones, wearables, and medical devices, showcasing their versatility.

Choosing the best methods for flexible PCB fabrication can be challenging. Various materials and techniques are available, each with distinct benefits. A study by Research and Markets highlights that the global flexible PCB market is evolving, with manufacturers investing in advanced technologies. However, the choices can overwhelm engineers. They must consider factors such as design complexity, production volume, and cost.

As the industry progresses, it's essential to reflect on the limitations of existing practices. Not all methods yield the desired quality or efficiency. Companies may find that suboptimal decisions can lead to higher rejection rates. In this context, understanding how to select the right fabrication methods is crucial for staying competitive.

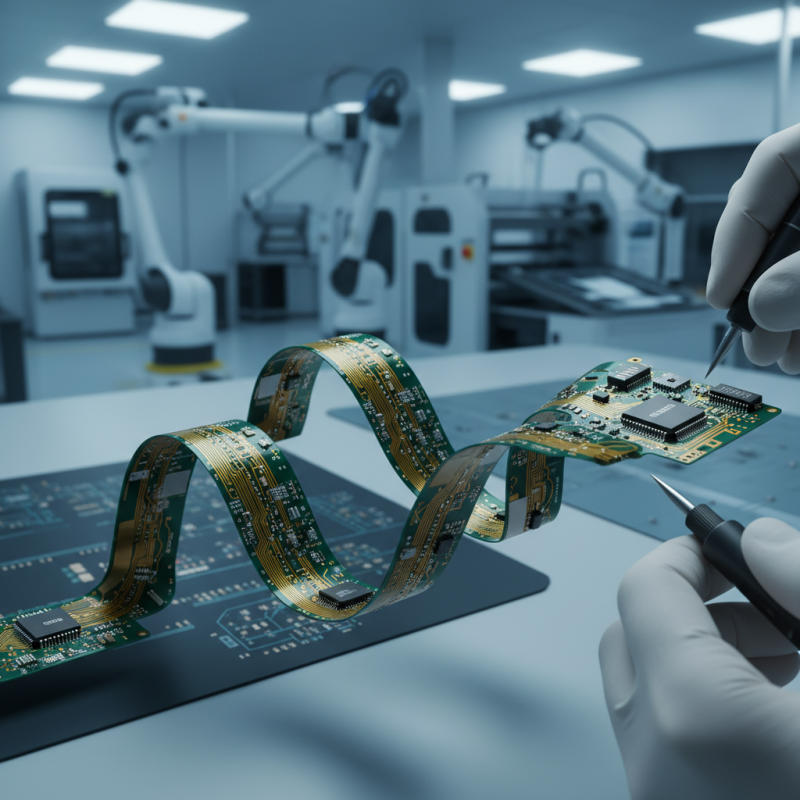

Flexible PCB fabrication is a growing field. The process allows for innovative designs that adapt to various applications. These are not just bendable circuits; they enable complex features in tiny spaces. Industries like medical devices and wearable tech rely heavily on flexible PCBs. They offer lightweight solutions and help save space.

Not all fabrication methods are equal. Each comes with its pros and cons. Some techniques might be more cost-effective but could compromise on quality. Others offer superior performance but require longer lead times. It’s essential to weigh these factors carefully. Understanding the specific requirements of your application is key. Sometimes, balancing cost and quality could lead to challenging decisions.

In some cases, the desired flexibility can conflict with durability. It's a design dilemma that many face. The challenges in selecting the right methods aren't just technical. They often require deep reflection on priorities and long-term goals. It’s not just about making a choice; it’s about making the right choice for future needs.

| Fabrication Method | Material Type | Layer Count | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Screen Printing | Polyimide | 1-2 Layers | Consumer Electronics | Cost-effective for low-volume production | May have lower resolution |

| Laser Cutting | PET | 1-4 Layers | Medical Devices | High precision, suitable for complex designs | Higher costs compared to traditional methods |

| Etching | FR-4 | 2-10 Layers | Aerospace | Excellent durability and thermal resistance | Longer production time |

| 3D Printing | Conductive Plastics | 1 Layer | Prototyping | Rapid prototyping and design flexibility | Lower mechanical properties |

When choosing flexible PCB manufacturing methods, several key factors come into play. The material selection is crucial. Different substrates, like polyimide or polyester, offer unique properties. Consider their thermal performance and flexibility. Each choice impacts the PCB's functionality and durability. However, not all materials suit every application. Reflect on your requirements carefully.

Another factor is the design complexity. Complex designs may require advanced manufacturing techniques. This can increase costs and lead times. Simplicity is often more effective. Yet, some projects demand intricate patterns. Balancing complexity and manufacturability is essential. It might be tempting to pursue elaborate designs, but practicality should be prioritized.

Cost considerations cannot be overlooked. While cheaper methods exist, they may sacrifice quality. Investing in reliable processes may prove worthwhile. It’s vital to evaluate long-term benefits. Ultimately, every decision comes with trade-offs. Being mindful of these factors will help you navigate the complexities of flexible PCB fabrication.

When considering flexible PCB fabrication techniques, several options stand out. Each has unique advantages and limitations. For instance, the subtractive method is widely used. It involves etching away excess copper from a flexible substrate. However, this technique can lead to material waste and requires precise control.

Another popular approach is additive manufacturing, or 3D printing of PCBs. This method allows for intricate designs and reduces material waste. Nonetheless, the technology is still evolving. The resolution may not always meet industry standards. It's vital to evaluate whether this technique fits your specific needs.

The lamination process is also worth discussing. It involves stacking layers of flexible material. This technique can create robust designs but may add complexity to the process. Moreover, achieving uniform bonding can be challenging. Each method has its place in the flexible PCB landscape, and careful consideration is needed to select the right one.

When choosing materials for flexible PCB fabrication, several factors come into play. Flexibility requires specific substrates to withstand bending and twisting. Polyimide is popular for its heat resistance and mechanical properties. However, recent studies suggest alternatives like PET could offer lower costs without sacrificing performance. Data indicates that 60% of manufacturers are exploring new materials to improve production efficiency.

Thermal conductivity is crucial. A material's ability to dissipate heat affects overall reliability. Research shows that copper cladding on polyimide substrates enhances thermal performance significantly. Yet, some designers overlook this aspect, leading to failures in high-performance applications. The right balance of thermal and mechanical properties can be elusive.

Moisture absorption also warrants attention. It impacts the longevity of flexible PCBs. A recent industry report revealed that improper material selection led to a 25% increase in failure rates in humid environments. Material choice demands careful consideration of end-use conditions. Ultimately, the optimum flexible PCB material will depend on specific application needs and environmental challenges. Experimentation may reveal surprising results.

The chart above shows the performance rating of different materials used for flexible PCB fabrication. Polyimide ranks highest in performance, followed by PEN and PET, indicating their suitability for high-quality flexible circuit applications.

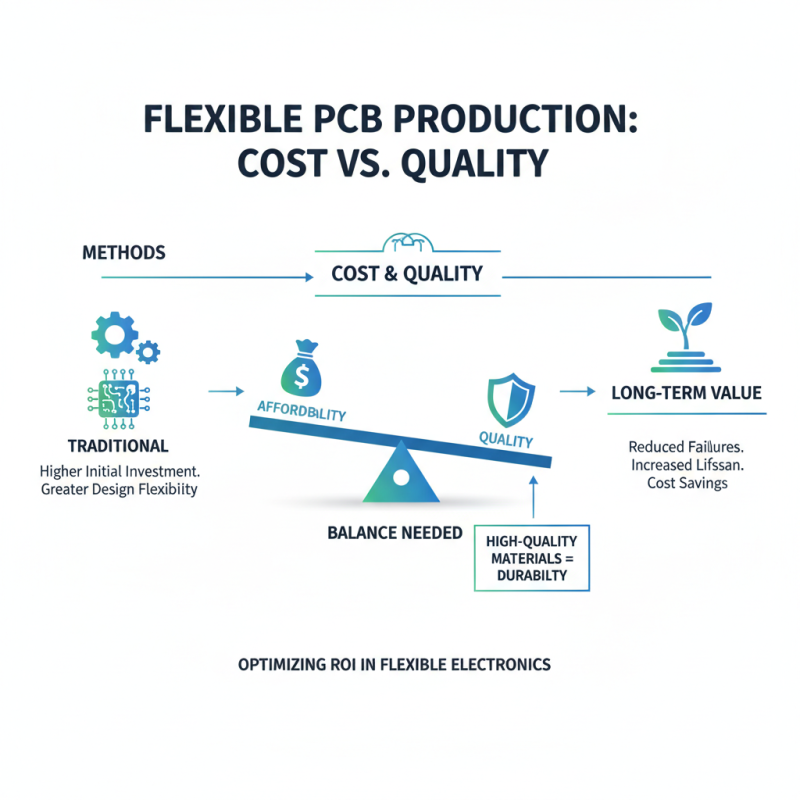

When considering flexible PCB production methods, cost plays a pivotal role. Different techniques come with varying price tags. For example, traditional methods may be cheaper upfront but lack the versatility needed for advanced designs. Manufacturers often struggle to balance quality with affordability. Investing in higher-quality materials can increase initial costs but may save in the long run.

Another factor is the scale of production. Small batches can be more expensive on a per-unit basis. This can deter companies from opting for sophisticated methods. However, bulk orders can significantly reduce overall costs. Evaluating the long-term needs versus short-term savings is crucial.

Lastly, operational expenses add complexity to decisions. Machinery maintenance, labor costs, and material sourcing may escalate quickly. Each of these elements requires careful analysis. Rushing decisions often leads to regret. It's worth taking time to assess all factors thoroughly. Aim for a balance between cost and functionality to avoid future complications.