Choosing the best PCB assembly service for your electronics projects can significantly impact the success of your designs and prototypes. As the industry continues to evolve, the importance of selecting a reliable partner becomes increasingly apparent. According to Dr. Alice Thompson, a leading expert in the PCB assembly field, "The quality of PCB assembly services can either make or break your project—the right choice ensures not just functionality, but innovation." This insight underscores the necessity of careful consideration during the selection process.

When embarking on your journey to find a suitable PCB assembly service, it’s essential to evaluate various factors such as expertise, technology employed, and turnaround times. A meticulous approach will help identify a partner who aligns with your project’s specific needs and standards. Understanding the intricacies of PCB assembly—from the sourcing of components to the final testing—can equip you with the information needed to make an informed decision.

In conclusion, the right PCB assembly service is not just a vendor; it’s a crucial ally in the development of your electronics projects. As you navigate through your options, keep Dr. Thompson’s perspective in mind, and prioritize quality, reliability, and communication to pave the way for successful outcomes in your engineering endeavors.

PCB assembly services play a critical role in the electronics industry, serving as the backbone for transforming innovative designs into functional products. According to a report by the IPC, the global PCB market is expected to exceed $80 billion by 2024, highlighting the growing demand for high-quality assembly services. These services involve multiple stages, including the placement of components onto the PCB, soldering, and testing. Each step is crucial; even minor errors in assembly can lead to significant performance issues or product failures, emphasizing the importance of choosing a reliable service provider.

A key factor in selecting a PCB assembly service is the level of expertise and technology they employ. Modern assembly processes increasingly rely on automated machinery and sophisticated inspection systems to ensure quality and precision. According to a study by MarketsandMarkets, the use of automated assembly systems is projected to grow substantially, driven by the need for faster production times and improved accuracy. In an industry where time-to-market can be a competitive advantage, understanding these capabilities will aid in determining the best fit for your electronics projects, ensuring that both quality and efficiency are prioritized throughout the production cycle.

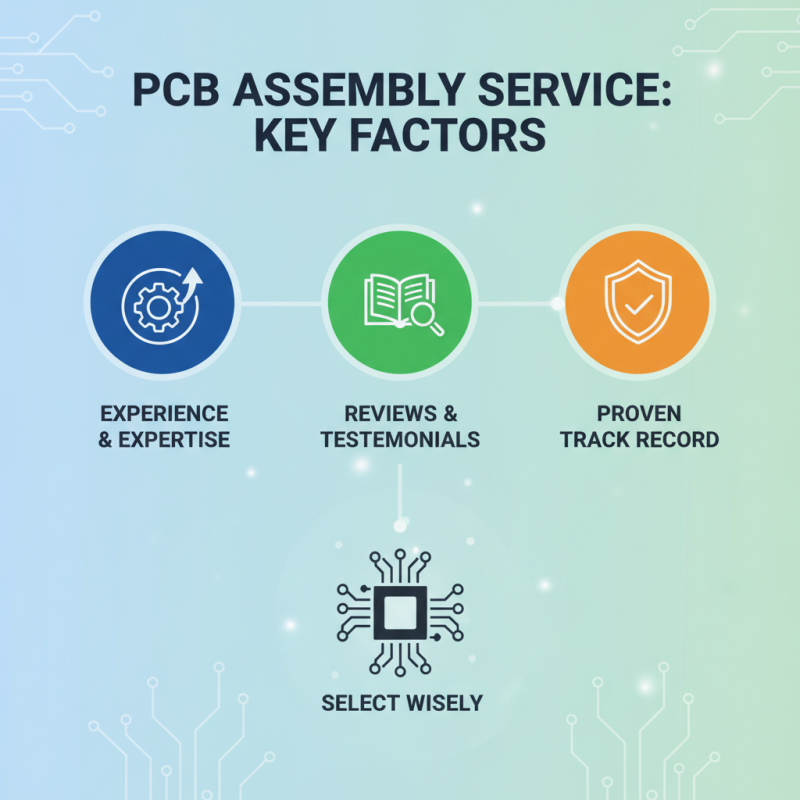

When selecting a PCB assembly service for your electronics projects, several key factors should be taken into account to ensure you make the best choice. First and foremost, consider the company's experience and expertise in the industry. A service provider with a proven track record will likely be more reliable and capable of handling the complexities of your specific project. Look for reviews and testimonials from previous clients to gauge their satisfaction and the quality of the assembly services provided.

Another crucial factor is the range of services offered by the PCB assembly company. Ideally, you want to partner with a service that can handle everything from prototyping to full-scale production. This versatility can save time and money as you won't need to switch vendors at different project stages. Additionally, inquire about their quality control processes. A robust quality assurance system is vital in guaranteeing that your PCBs meet the necessary standards and specifications, ultimately influencing the performance of your final product.

When seeking the best PCB assembly service for your electronics projects, the experience and expertise of the provider play a critical role in ensuring quality and reliability. An experienced PCB assembly service typically boasts a portfolio that showcases their past projects, which can provide insight into their capability to handle various complexities in design and manufacturing. Look for providers who have worked with a diverse range of industries, as this broad exposure often indicates a deeper understanding of different requirements and standards.

Furthermore, assessing the expertise of the assembly team is equally vital. Inquire about the qualifications and certifications of the engineers and technicians involved in the assembly process. A well-trained team familiar with the latest technologies and manufacturing processes is more likely to produce high-quality products. Additionally, consider the provider's commitment to ongoing training and development for their staff, as this demonstrates their dedication to staying current with advancements in PCB technology and industry standards. By thoroughly evaluating both the experience and expertise of PCB assembly providers, you can make a more informed decision that aligns with your project needs.

| Criteria | Description | Rating (1-5) |

|---|---|---|

| Experience | Number of years in the PCB assembly industry. | 4 |

| Certifications | Relevant industry certifications (e.g., ISO, IPC). | 5 |

| Technical Capabilities | Range of technologies and assembly methods offered. | 4 |

| Customer Support | Quality of customer service and support provided. | 5 |

| Turnaround Time | Speed of service from order to delivery. | 3 |

| Pricing | Affordability compared to competitors. | 4 |

When selecting a PCB assembly service for your electronics projects, it's crucial to compare the costs and services offered by various assemblers. According to industry reports, the average cost of PCB assembly can vary significantly, ranging from $0.01 to $0.10 per pin, depending on the complexity of the design and the volume of production. For instance, low-volume assemblies typically cost more per unit, while economies of scale can reduce costs substantially for high-volume orders. This cost analysis is essential, as even small differences in pricing can impact your overall project budget.

In addition to pricing, examining the services provided by PCB assemblers is equally important. Many companies offer a range of services, including design assistance, component sourcing, and prototype manufacturing. A comprehensive service package can save time and reduce the need for multiple vendors. Research shows that 70% of successful electronics projects are completed within the estimated timeframe, primarily when utilizing a service that supports rapid prototyping and offers extensive assembly capabilities.

Tips: Always request quotes from multiple PCB assemblers and ensure that you clarify what is included in the price, such as testing and quality assurance services. Additionally, consider choosing a provider that has experience in your specific industry, as their familiarity with your requirements can greatly enhance the efficiency and effectiveness of the assembly process.

When selecting a PCB assembly service for your electronics projects, quality control measures should be a top priority. A reliable service should have a robust quality assurance process that includes multiple inspection stages. Look for companies that utilize automated optical inspection (AOI) systems to detect flaws early in the production cycle. This can help to identify issues such as misalignments, soldering defects, and component placement errors before they escalate, ensuring a higher quality final product.

Tips: Always inquire about the quality control certifications the service holds, such as IPC standards. These certifications indicate that the service adheres to established industry best practices, which can significantly reduce the risk of defects in your PCB assembly.

Additionally, it's essential to understand how the assembly service performs functional testing on their PCBs. This testing verifies that the assembled boards meet the required specifications and perform their intended functions correctly. Ask about their testing methodologies, whether they conduct in-circuit tests (ICT) or functional tests, and how they handle any issues that may arise during this process.

Tips: Request samples or case studies demonstrating the service's commitment to quality control. This will provide you with real-world insight into their capabilities and how well they align with your project's needs.