In the rapidly evolving world of electronics, choosing the right flex PCB board is critical. Industry expert Dr. Emily Chen states, "The right flex PCB can make or break your project." This highlights the importance of careful selection when working on circuit designs.

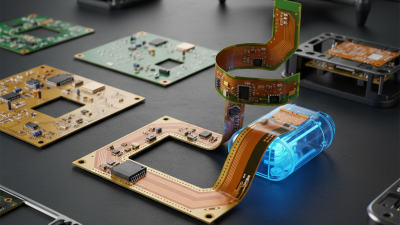

Flex PCB boards offer unique advantages, such as versatility and lightweight construction. They can fit into compact spaces and can bend to meet design needs. However, the choices can be overwhelming. With various types, materials, and features available, it's easy to feel lost.

Understanding the specific requirements of your project is essential. Consider factors like the intended application, environment, and budget. Flex PCB boards come in different thicknesses and materials, impacting both performance and cost. Reflecting on these can help lead to a better-informed decision.

Flexible Printed Circuit Boards (Flex PCBs) are revolutionizing electronic design. They provide unique advantages such as lightweight construction and versatility in applications. By 2025, the global flex PCB market is projected to reach approximately $27 billion, according to industry reports. This growth highlights the increasing adoption of these boards across various sectors, including consumer electronics, automotive, and medical devices.

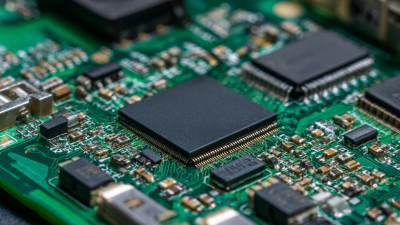

Understanding the basic components of a flex PCB is essential for any project. Typically, these boards consist of a flexible substrate that can bend and twist without compromising functionality. This flexibility allows for innovative designs in compact spaces. For instance, in wearables, the integration of flex PCBs enables sleek, lightweight devices that conform to body shapes. However, not all projects require this flexibility. Sometimes, traditional rigid PCBs may suffice for less demanding applications.

Choosing the right flex PCB involves evaluating needs and potential applications. It’s crucial to consider factors like the board’s manufacturing process and material composition. Not every design may benefit from a flex PCB's advantages. In some cases, cost considerations could outweigh the benefits. Reflecting on these factors will ensure that the right choice is made for your specific project requirements.

When choosing a flex PCB for your project, consider the material types carefully. Different materials offer unique properties, impact flexibility, and performance. For example, polyimide is popular for its high heat resistance. However, it can be more expensive than other options. Think about your project's budget and requirements.

Moreover, the desired flexibility level matters. Some projects need extreme bending while others do not. Materials like polyester can provide moderate flexibility. Make sure to evaluate your design constraints. Ask yourself if the chosen material will endure the operational conditions.

Thickness is another crucial consideration. Thinner materials may be easier to fit in tight spaces, but they can be less robust. Balancing thickness and durability is challenging. Failure can happen if you don’t choose wisely. Conduct trials, if possible, to assess the performance of different materials in real-life scenarios. Remember, every choice has its ups and downs; learn from what works and what doesn’t.

This bar chart compares the cost per square meter for different types of flex PCB materials. The cost can vary significantly based on the material used, which is a key consideration when selecting the right flex PCB for your project.

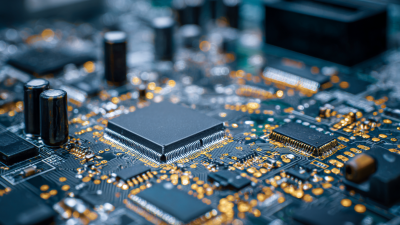

When evaluating design requirements for a flex PCB board, the first step is to assess your project’s specifications. Flex PCBs are lightweight, thin, and designed for flexibility. According to a recent industry report, the global flexible printed circuit boards market is projected to reach $30 billion by 2027, driven by demand in the automotive and consumer electronics sectors. This trend suggests that understanding your specific needs is crucial for a successful project.

Consider the environment your flex PCB will operate in. Will it face high temperatures? Humidity can also be a concern. Some designs do not accommodate these factors well, leading to failures. Do not overlook the mechanical durability required for your application. A report from IPC indicates that 35% of failure cases in PCBs are due to mechanical stress. Your chosen material must withstand these conditions or you'll face costly redesigns later on.

Lastly, think about the complexity of your circuitry. High-density designs may require specialized manufacturing techniques. Yet, intricate designs can introduce risks if not properly planned. Designers sometimes rush this process, sacrificing quality for speed. Aim for iterative testing and adjustments. The right design can enhance performance and longevity, ensuring your project succeeds in its intended application.

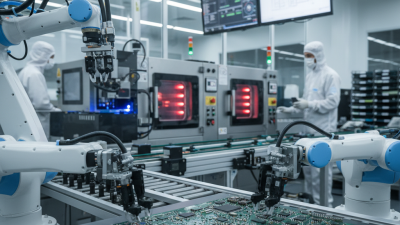

When comparing manufacturing processes for different flex PCB types, several factors come into play. The most common types are single-sided, double-sided, and multi-layer flex PCBs. Each type has unique characteristics that influence production techniques. For instance, single-sided boards are generally easier and cheaper to produce. They can be manufactured quickly due to their straightforward design.

On the other hand, multi-layer flex PCBs require more complex processes. These include lamination and drilling, which can lead to longer production times. They are ideal for dense applications, but cost may increase. Quality control becomes crucial when dealing with multiple layers. Any misalignment could cause significant issues.

Another manufacturing consideration is material choice. Selecting the right substrate impacts durability and performance. Polyimide is popular due to its excellent heat resistance. However, traditional FR-4 materials often yield lower production costs. It’s essential to weigh the benefits against potential downsides. Production errors, like poor layer adhesion, can happen and are costly. Balancing cost and quality requires careful thought.

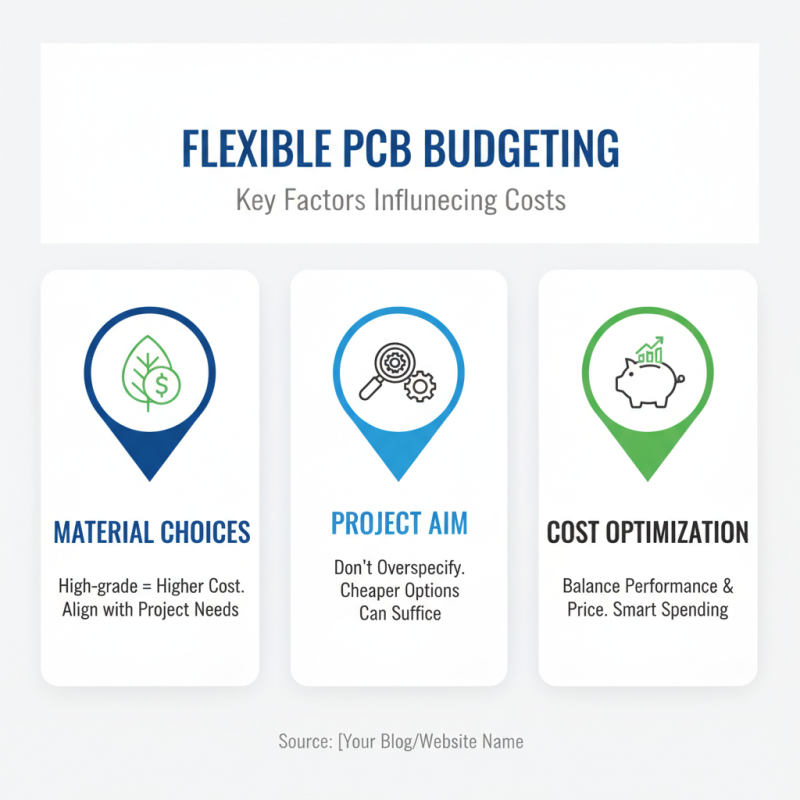

When developing a flexible PCB, budgeting can be tricky. Various factors influence costs. Material choices play a big role. High-grade materials may seem ideal but can easily inflate your budget. Be mindful of your project's aim. Sometimes, a less expensive option suffices.

Production volume also affects pricing. Smaller runs often lead to higher per-unit costs. It's essential to evaluate your needs. A larger order may provide savings but requires initial investment. Many overlook additional costs, like design and testing. These can add up quickly.

Consider timeline as well. Rush orders can significantly raise expenses. Adjusting timelines can balance quality and cost. Regular reviews of your budget help in staying on track. Regular reflection on these topics ensures your project remains viable.