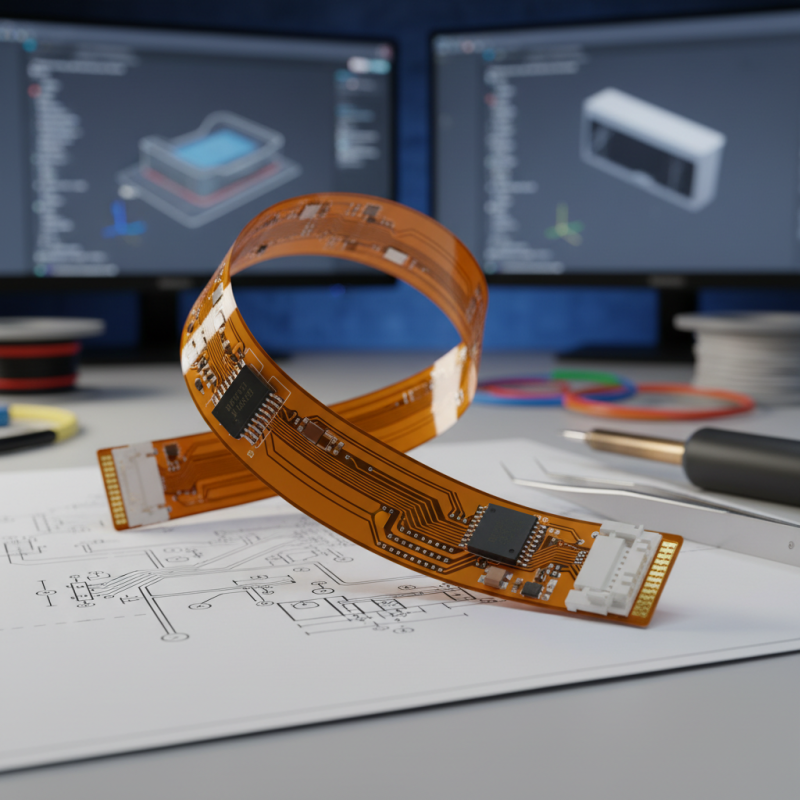

Choosing the right flex PCB board for your project is crucial to ensure functionality, reliability, and effectiveness. With the rapid advancement of technology and the increasing demand for compact electronic devices, flex PCBs have emerged as an essential component in various applications, ranging from consumer electronics to aerospace. As a versatile solution, these printed circuit boards offer manufacturers the flexibility to design intricate layouts that can fit into the most challenging spaces.

When selecting the appropriate flex PCB board, it is vital to consider several key factors, including the specific requirements of your application, the materials used, and the manufacturing processes involved. Understanding the characteristics of different types of flex PCBs can significantly impact the performance and durability of your final product. By taking the time to analyze your project’s needs and the available options in the market, you can make a more informed decision that aligns with your design goals and technical specifications.

This guide will equip you with the fundamental knowledge required to navigate the complexities of flex PCB board selection, providing insights into the various design considerations and best practices to optimize your project outcomes. As you embark on this journey, embracing the right approach to choose your flex PCB board will ultimately contribute to the success of your innovative electronic solutions.

Flexible printed circuit boards (Flex PCBs) have gained significant traction in various industries due to their unique benefits and adaptability. Unlike traditional rigid PCBs, Flex PCBs are made from pliable materials allowing them to bend, twist, and conform to fit into compact spaces. This flexibility opens up opportunities in applications ranging from consumer electronics to medical devices. According to a report by Fortune Business Insights, the global flex PCB market is projected to reach $28.69 billion by 2027, growing at a CAGR of 7.9% from 2020 to 2027. This growth underscores the increasing reliance on these designs where space, weight, and functionality are critical.

Understanding the basic structure and advantages of Flex PCBs can help engineers make informed choices for their projects. The ability of Flex PCBs to withstand high temperatures and their excellent electrical performance make them ideal for high-density interconnections. Additionally, their lightweight nature contributes to reducing the overall weight of products, a significant factor in aerospace and automotive industries, where every gram matters. A study published in the Journal of Electronics Materials highlighted that Flex PCBs can reduce the total weight of electronic assemblies by up to 40%, significantly enhancing the overall efficiency of the end product. Moreover, the ease of integration into three-dimensional shapes allows for more innovative design capabilities that are not feasible with traditional PCBs.

This chart illustrates the advantages of Flex PCBs based on various key criteria. Each advantage is rated on a scale from 0 to 100, highlighting aspects such as space-saving design, lightweight materials, flexibility, durability, and cost-effectiveness that make Flex PCBs a preferred choice for many electronic projects.

When it comes to selecting the right flexible printed circuit board (Flex PCB) for your project, several key factors must be taken into account to ensure compatibility and functionality. One of the primary considerations is the substrate material. Materials like polyimide offer excellent flexibility and thermal stability, which are crucial for applications requiring bending or twisting. Assessing the specific environment in which the PCB will operate is vital, as this will inform the choice of material based on factors such as temperature fluctuations and exposure to chemicals.

Another critical factor to consider is the number of layers required for your design. Single-layer boards are less complex and more affordable, while multilayer boards provide greater circuit density and functionality. It's essential to strike a balance between complexity and cost-effectiveness according to the project’s requirements. Also, consider the thickness of the copper traces, as this affects the board’s flexibility and performance under stress.

**Tips**: Before finalizing your choice, prototype different configurations of your Flex PCB to evaluate their performance under real-world conditions. Additionally, consult with your manufacturing partner to gain insights into their capabilities and limitations; this collaboration can help refine your design to align with production feasibility. Finally, keep in mind the electrical and thermal requirements of your application to avoid potential issues later on.

Flex PCBs, or flexible printed circuit boards, are gaining traction in numerous modern technology applications due to their adaptable nature and lightweight characteristics. A recent industry report indicates that the global flex PCB market is expected to reach around $35 billion by 2025, highlighting the growing reliance on these components in various sectors. Among the most common applications are consumer electronics, medical devices, and automotive technology. In consumer electronics, flex PCBs are essential for the compact designs of smartphones and tablets, allowing for intricate circuitry in limited spaces.

Additionally, in the medical field, flex PCBs are utilized in portable devices like cardiac monitors and wearable fitness trackers, which have surged in popularity. The ability of flex PCBs to endure bending and twisting while maintaining performance makes them ideal for these applications. In automotive technology, flexible circuits are increasingly used in advanced driver-assistance systems (ADAS), contributing to improved safety and efficiency. According to a market analysis, the automotive sector alone is projected to account for 15% of the flex PCB market by 2025, driven by the integration of smart technologies in vehicles.

Tips: When selecting a flex PCB for your project, consider factors such as the intended application, environmental conditions, and mechanical flexibility requirements. Ensuring compliance with industry standards can also enhance reliability. Keeping an eye on emerging technologies can help identify new applications and potential innovations, allowing for a competitive edge in your market.

When selecting the right flex PCB board for your project, one of the most critical aspects to consider is the material used in its construction. The type of substrate significantly influences the performance, flexibility, and durability of the final product. According to a report by TechNavio, the global flexible PCB market is expected to grow at a CAGR of over 10% from 2021 to 2025, highlighting the increasing demand for high-performance materials. Common materials include polyimide, polyester, and FR-4; however, each offers distinct advantages and limitations depending on the operating environment and application requirements.

For instance, polyimide is renowned for its exceptional thermal stability and high chemical resistance, making it suitable for applications in extreme conditions, such as aerospace and automotive sectors. In contrast, polyester-based flex PCBs are often highlighted for their cost-effectiveness and lighter weight, although they typically have lower thermal resistance compared to polyimide substrates. A study by IDTechEx emphasizes the growing trend towards using composite materials, which can enhance mechanical properties while maintaining flexibility. Evaluating these material options carefully will not only optimize the functionality of your project but could also lead to cost efficiencies over time. As industries increasingly prioritize lightweight and compact designs, understanding material characteristics will be pivotal for engineers and manufacturers alike.

| Material Type | Thickness (mm) | Flexibility Rating | Operating Temperature (°C) | Application Suitability |

|---|---|---|---|---|

| Polyimide (PI) | 0.025 - 0.5 | High | -269 to 400 | Aerospace, Military |

| Polyester (PET) | 0.5 - 1.0 | Moderate | -40 to 150 | Consumer Electronics |

| FR-4 | 0.2 - 1.5 | Low | -40 to 130 | General Use, Circuit Boards |

| Liquid Crystal Polymer (LCP) | 0.025 - 0.1 | Very High | -269 to 250 | Telecommunications, RF Applications |

| Epoxy | 0.1 - 1.0 | Low to Moderate | -40 to 120 | Automotive, Household Applications |

When choosing the right flexible printed circuit board (flex PCB) for your project, evaluating design and manufacturing capabilities is crucial. A well-established manufacturer should be capable of providing advanced design services that align with your project's specifications. This includes understanding the complex dynamics of the circuit layout, accommodating various functional requirements, and ensuring the overall reliability of the board under different conditions. Collaborating closely with the design team can help optimize the design for manufacturability, ensuring that all components meet your performance expectations.

Additionally, assessing manufacturing capabilities involves more than just examining the equipment and technology employed by the manufacturer. It requires an understanding of their quality assurance processes, production capacity, and ability to scale with your project's growth. Look for manufacturers that utilize cutting-edge techniques and materials, which can enhance the durability and flexibility of the PCB. Furthermore, their experience with different industries can provide valuable insights and innovations that are adaptable to your specific needs. Prioritizing these factors ensures a smoother development process and a final product that meets stringent performance standards.