The rapid evolution of technology has ushered in a new era for the electronics industry, particularly with the advent of flexible printed circuit (FPC) technology. According to a recent report from MarketsandMarkets, the global flexible printed circuit market is projected to grow from $18.2 billion in 2020 to $30.3 billion by 2025, at a CAGR of 10.3%. This growth is driven by increasing demand for lightweight, compact electronic devices across various sectors, including consumer electronics, automotive, and healthcare. As industries continue to embrace miniaturization and advanced functionalities, FPCs offer significant advantages such as design flexibility, improved reliability, and reduced assembly costs.

The integration of FPC technology is thus not only enhancing the performance of electronic gadgets but also paving the way for groundbreaking innovations in smart wearable devices, IoT applications, and beyond. This article delves into the future of electronics innovations shaped by advancements in flexible printed circuits, highlighting emerging trends and possibilities that lie ahead.

Flexible printed circuits (FPCs) are poised to revolutionize consumer electronics, offering unprecedented versatility and innovation in product design and functionality. As the demand for lighter, thinner, and more adaptable devices rises, the adoption of FPC technology becomes increasingly essential. In 2023, the flexible electronics and circuits market is projected to reach $31.57 billion, with a compound annual growth rate of 7.43% anticipated over the forecast period. This growth is primarily driven by advancements in applications such as smartphones, wearables, and smart home devices, which heavily rely on the integration of flexible circuitry.

Moreover, the ongoing development of high-performance materials and manufacturing techniques is accelerating the capabilities of FPCs. Innovations in printing technologies, such as inkjet and screen printing, enable the creation of complex electronic designs that were previously unattainable. As these technologies evolve, they will provide new opportunities for the deployment of flexible circuits in diverse areas including displays, photovoltaic systems, and lighting solutions. The trend towards miniaturization and improved efficiency reinforces the significance of flexible printed circuit technology in shaping the future landscape of consumer electronics.

| Application Area | Description | Benefits | Future Trends |

|---|---|---|---|

| Wearable Devices | Integration of sensors and circuits into fabric. | Lightweight, flexible, and comfortable to wear. | Advances in textile electronics and health monitoring. |

| Smart Appliances | Flexible circuits in kitchen or home devices. | Enhanced functionality with space-saving designs. | Increased connectivity and energy efficiency. |

| Automotive Applications | Flexible circuits for instrumentation and entertainment systems. | Durable, reliable, and can conform to space constraints. | Integration with autonomous systems and smart features. |

| Healthcare Devices | Wearable health monitors and flexible sensors. | Real-time health monitoring and diagnostics. | Personalized health management and telemedicine. |

| Consumer Electronics | Flexible displays and circuit boards in portable devices. | Sleeker designs and improved user experience. | Emergence of foldable tech and enhanced interactivity. |

The integration of flexible printed circuit (FPC) technology in wearable health devices marks a significant advancement in the field of electronics, driving innovations that cater to the growing demand for efficient and versatile health monitoring solutions. According to a recent report by Research and Markets, the global wearable health technology market is projected to reach $60 billion by 2023, highlighting the increasing adoption of devices that harness the potential of FPC technology. With the ability to conform to various shapes and surfaces, flexible circuits enable manufacturers to develop slimmer, lighter, and more ergonomic designs.

Moreover, flexible circuit technology plays a crucial role in enhancing the functionalities of wearable devices. As per a study by IDTechEx, the market for flexible electronic devices is expected to surpass $95 billion by 2030, largely driven by innovations in health tech. This includes devices capable of continuous monitoring of vital signs, such as heart rate and blood pressure, providing real-time data to users. The seamless integration of these flexible circuits not only improves device performance but also enhances user comfort and wearability, making health monitoring more accessible and effective than ever before.

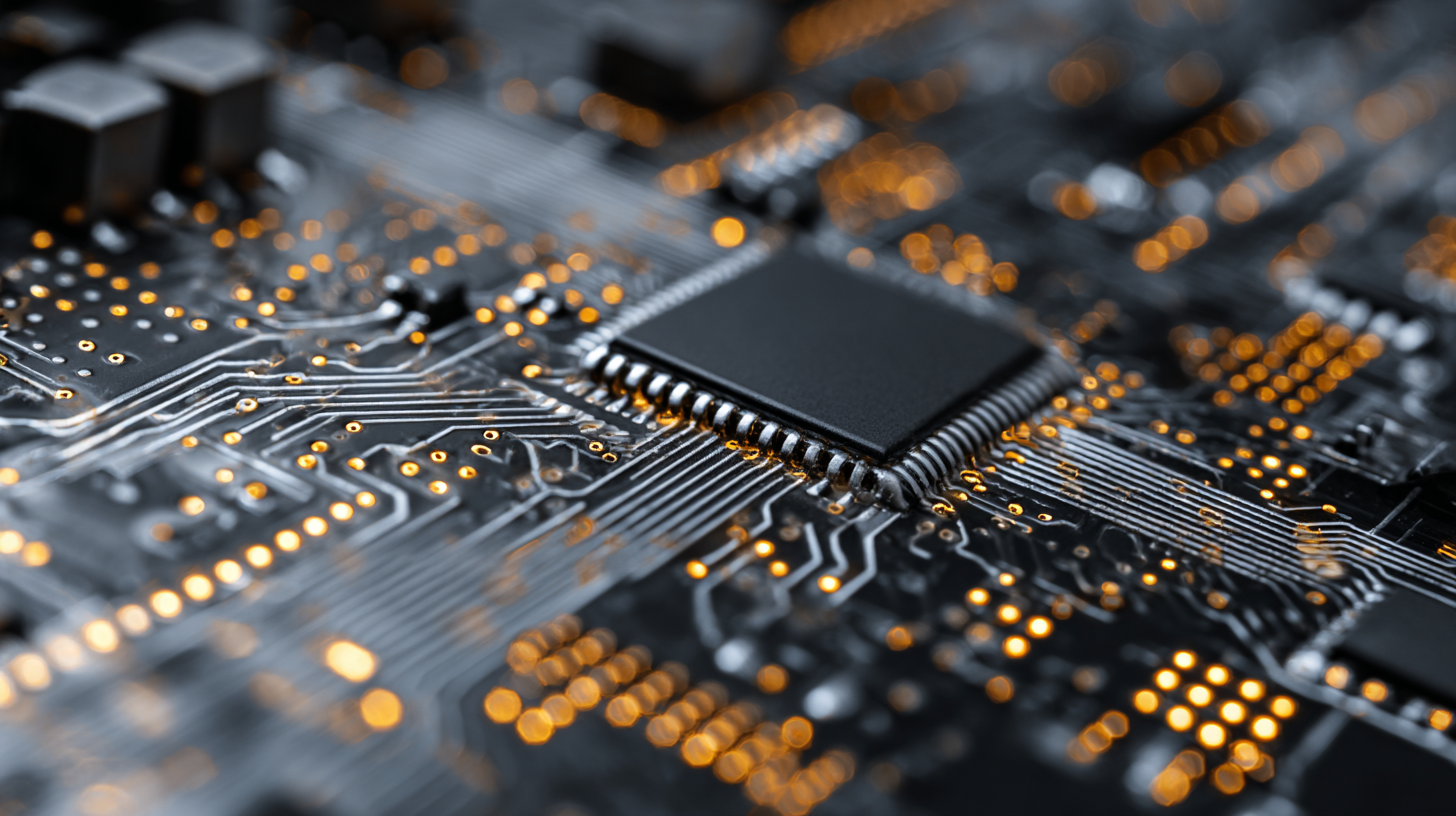

Flexible Printed Circuit Boards (PCBs) are at the forefront of revolutionizing

Internet of Things (IoT) connectivity solutions. As devices become smaller and more interconnected, the need for

lightweight, flexible, and reliable circuitry has never been greater.

Flexible PCBs can easily conform to the compact designs of modern gadgets, facilitating advanced integration of sensors

and communication modules necessary for IoT applications. This technology unlocks new possibilities for wearable devices

and smart appliances, enhancing their efficiency and functionality in a connected environment.

Flexible Printed Circuit Boards (PCBs) are at the forefront of revolutionizing

Internet of Things (IoT) connectivity solutions. As devices become smaller and more interconnected, the need for

lightweight, flexible, and reliable circuitry has never been greater.

Flexible PCBs can easily conform to the compact designs of modern gadgets, facilitating advanced integration of sensors

and communication modules necessary for IoT applications. This technology unlocks new possibilities for wearable devices

and smart appliances, enhancing their efficiency and functionality in a connected environment.

Tips: When designing flexible PCBs for IoT devices, consider the thermal properties

and material selections that will withstand varying conditions. Additionally, ensure that the layout minimizes electromagnetic

interference, as this can significantly impact signal integrity and device performance.

The ability of flexible PCBs to support high-density interconnections without sacrificing performance is a game-changer

for industries ranging from healthcare to home automation. By enabling more seamless communication between devices, these circuits

play a critical role in realizing the full potential of IoT ecosystems. As the demand for innovative connectivity solutions grows,

flexible PCB technology will continue to evolve, paving the way for smarter, more efficient electronic devices.

Tips: Collaborate with a PCB manufacturing partner who specializes in flexible technology

to ensure optimal design and production processes. Keep abreast of emerging trends in IoT to leverage new capabilities that flexible

PCBs can offer in future projects.

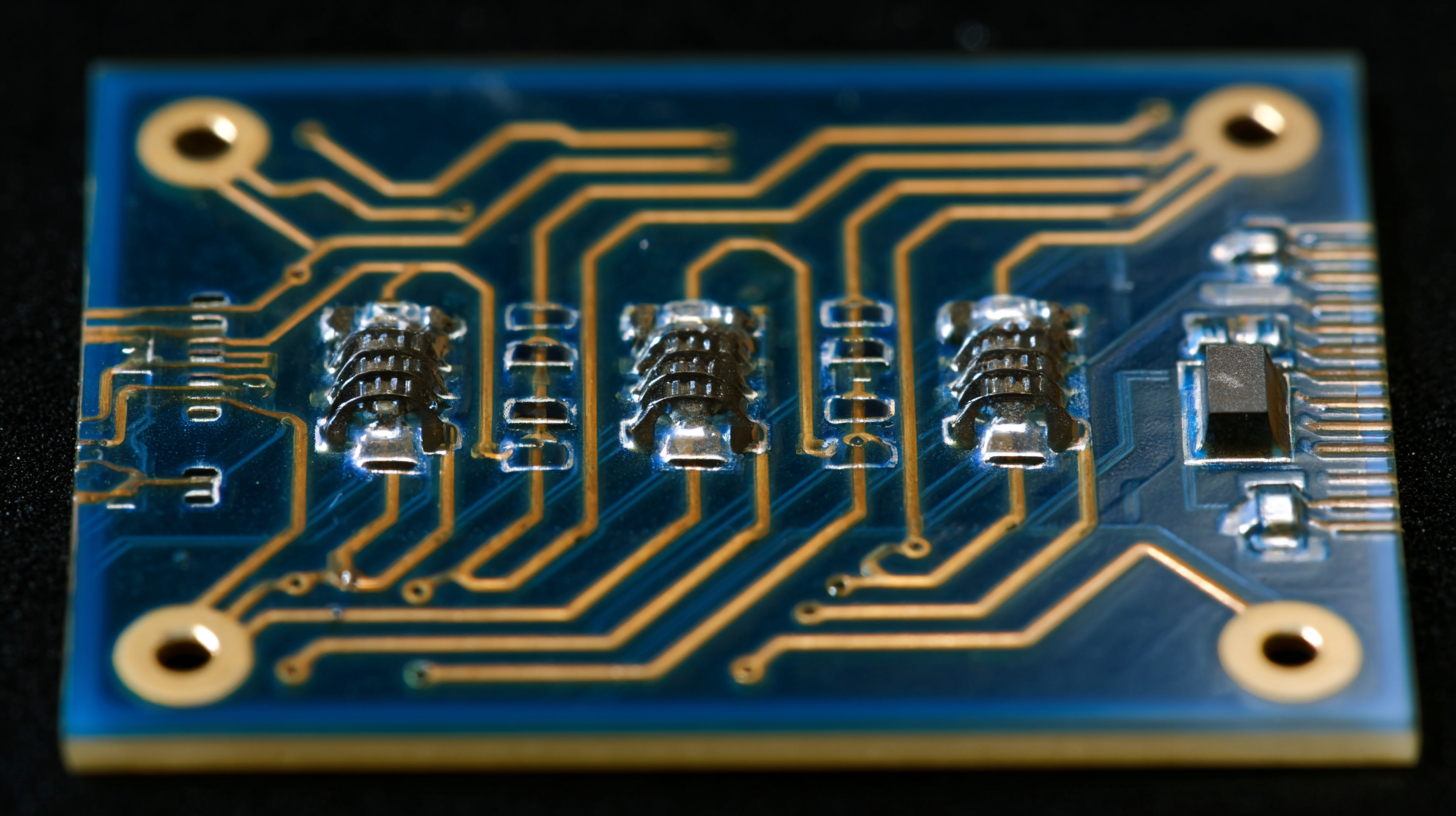

Implementing flexible printed circuit technology in industrial electronics presents a compelling cost-benefit landscape. The projected growth of the flexible PCBs market, anticipated to reach USD 61.75 billion by 2032, underscores the rising demand for compact, lightweight, and adaptable electronic solutions. Industries such as automotive, wearables, and advanced medical devices are driving this expansion as manufacturers seek to innovate and integrate more versatile design options into their products. The flexible nature of these circuits allows for unique configurations, leading to increased functionality while potentially reducing material costs and overall production expenses.

Moreover, the robust growth of the overall flexible electronics market, forecasted to rise to USD 71.99 billion by 2032 with a CAGR of 11.6%, highlights the competitive advantage businesses can gain by adopting such technologies. This suggests that investing in flexible printed circuits could not only enhance product performance but also significantly lower long-term operational costs. The ability to streamline designs and reduce weight can improve efficiency and sustainability, making flexible circuits a wise choice for companies aiming to remain at the forefront of technological advancement in the rapidly evolving electronics landscape.

The adoption of flexible printed circuit (FPC) technology is poised to reshape the landscape of electronics innovation, yet it faces several trends and challenges that influence its integration. One notable trend is the increasing demand for miniaturization in electronic devices. As consumer electronics evolve towards more compact and lightweight designs, FPCs, with their ability to bend and conform to various shapes, become vital in enabling this shift. Industries such as wearables and mobile devices are leading the charge, incorporating FPCs to meet the expectations of consumers for sleek designs without compromising functionality.

However, the path to widespread adoption is not without its challenges. Manufacturing complexities and higher production costs can hinder the scalability of FPC technology. Additionally, there is a need for improved materials and manufacturing processes to enhance the reliability and durability of flexible circuits, particularly in demanding applications. The industry also faces a knowledge gap, as many engineers and designers lack experience with FPCs, resulting in a slower learning curve. Addressing these challenges through collaboration, enhanced training, and investment in research will be crucial for unlocking the full potential of flexible printed circuit technology in the future of electronics.