In the fast-evolving world of electronics, the demand for reliable and high-performing components has never been greater. Rigid PCBs, or printed circuit boards, have become a cornerstone of modern electronic devices, serving as the foundation upon which intricate circuitry is built. According to Dr. Emily Tran, a leading expert in PCB design, "The choice of rigid PCBs directly influences the durability and efficiency of electronic products." This highlights the critical role that rigid PCBs play in ensuring that devices function correctly under various environmental conditions.

As industries continue to innovate, the complexities of designs necessitate a deeper understanding of how to choose the right rigid PCB. Factors such as material selection, thickness, and layering can significantly affect a product's performance and longevity. This introductory exploration will delve into the essentials of rigid PCBs, offering insights into their applications and the considerations necessary for making informed choices in selecting the appropriate rigid PCB for diverse electronic needs.

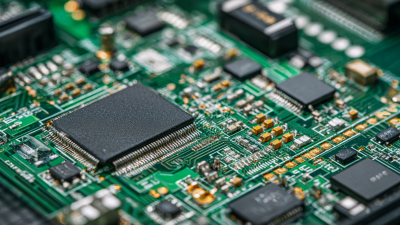

Rigid printed circuit boards (PCBs) play a pivotal role in contemporary electronic devices, serving as the foundational backbone that supports various electronic components. Their sturdiness and stability make them ideal for applications where precise connections and durability are paramount. In an era where devices are becoming increasingly compact yet complex, the demand for robust PCBs is more critical than ever. They ensure that electronic components are securely held in place, preventing damage during operation and transportation, which is essential for maintaining the reliability of modern gadgets.

Choosing the right rigid PCB involves considering several factors, including material composition, layer count, and thermal management capabilities. High-quality materials contribute to better electrical performance and longevity, while a proper layer count can optimize space for intricate circuits without compromising functionality. Additionally, thermal management is crucial, as it ensures that devices operate efficiently without overheating. As technology continues to advance, understanding these parameters becomes essential for engineers and designers aiming to create innovative and reliable electronic products in today's fast-paced market.

Rigid Printed Circuit Boards (PCBs) offer a multitude of advantages that make them indispensable in modern electronic applications. Firstly, their structural integrity ensures reliable performance and durability in various environments. Rigid PCBs maintain their shape and provide excellent mechanical support, making them ideal for devices that experience frequent movement or require precise alignment between components. This stability is especially crucial in industries such as aerospace, automotive, and medical, where failure can lead to significant safety risks.

In addition to their robustness, rigid PCBs support high-density packaging. They can accommodate a greater number of components compared to flexible boards, which leads to smaller and more compact electronic designs. This is particularly beneficial in consumer electronics, where space is often at a premium. Furthermore, rigid PCBs are compatible with automated manufacturing processes, enhancing production efficiency and reducing costs. Their ability to facilitate complex circuit designs while ensuring signal integrity makes them a preferred choice for high-performance applications, firmly establishing their role in the ongoing evolution of electronics technology.

When selecting rigid printed circuit boards (PCBs) for electronic projects, several critical factors must be considered to ensure optimal performance and reliability. First and foremost, the material used in the PCB is essential. FR-4, a widely used material, offers excellent mechanical strength and thermal stability, making it suitable for various applications. According to a 2023 IPC report, more than 80% of manufacturers prefer FR-4 for its cost-effectiveness and reliability in high-frequency applications.

Another critical factor is the thickness and layer count of the PCB. Thicker boards can provide better support for heavier components and enhance durability, while multi-layer designs allow for advanced circuitry and complex electromechanical integration. The same IPC report indicates that the average layer count for rigid PCBs has increased from 4 to 8 layers in high-performance devices over the last five years, reflecting the growing demand for compact and sophisticated electronic solutions. Additionally, designers must consider the tolerances and specifications required for their projects, as precision in these areas greatly affects the final product's functionality and longevity. Overall, understanding these factors is vital for anyone venturing into the development of modern electronic devices.

Rigid printed circuit boards (PCBs) and flexible PCBs each play critical roles in the landscape of modern electronics, but their unique characteristics cater to different applications. Rigid PCBs are generally preferred for their durability and robust design, making them suitable for high-density applications such as computers and telecommunications devices. According to a report by IPC, the global rigid PCB market is projected to reach approximately $35 billion by 2025. This growth is driven by increasing demand for high-performance electronic devices, which require reliable and consistent connection pathways that rigid PCBs provide.

On the other hand, flexible PCBs offer adaptability and space-saving advantages, making them ideal for compact electronic devices like wearables and mobile devices. Their ability to bend and twist allows for innovative designs in applications where space and weight are critical. However, flexible PCBs sometimes have limitations in terms of the number of layers and overall complexity compared to their rigid counterparts. A market analysis by Research and Markets estimates that the flexible PCB market will reach around $28 billion by 2026, reflecting an increasing trend towards portable and multifunctional devices. When choosing between these two types of PCBs, designers must consider the specific requirements of their applications, including mechanical strength, thermal performance, and manufacturing costs.

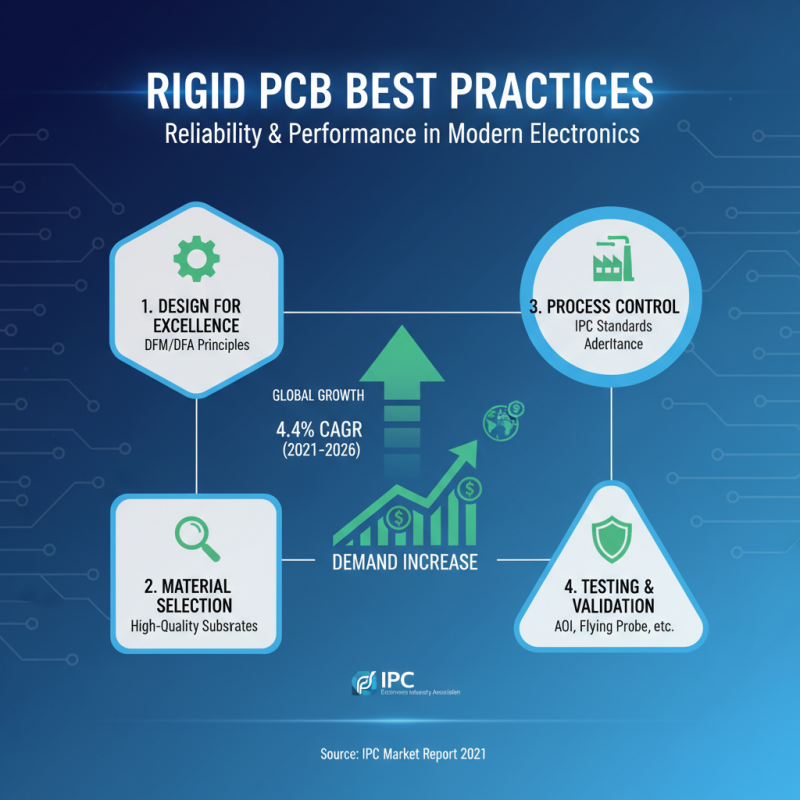

When designing and manufacturing rigid printed circuit boards (PCBs), adherence to best practices is crucial to ensure reliability and performance in modern electronics. According to a report by IPC, the global trade association for the electronics industry, the demand for rigid PCBs is projected to grow at a compound annual growth rate (CAGR) of 4.4% from 2021 to 2026. This growth emphasizes the need for precise engineering and manufacturing processes to meet evolving technological requirements.

One essential practice is selecting the right materials. High-quality FR-4 is frequently utilized for its excellent dielectric properties and thermal stability. Additionally, the use of multilayer PCBs can significantly enhance circuit density, allowing for more complex designs without compromising on size. A study from Research and Markets highlights that multilayer PCBs are expected to hold a significant market share due to their advantages in compact circuit design and performance optimization.

Furthermore, effective manufacturing techniques such as automated optical inspection (AOI) and X-ray inspection play a pivotal role in producing defect-free PCBs. Reports from reputable PCB manufacturers reveal that integrating these technologies can reduce the defect rate by up to 30%, thereby enhancing the overall quality of the final product. Emphasizing these best practices not only streamlines production but also ensures that the rigid PCBs meet the rigorous demands of various applications, from consumer electronics to critical aerospace components.