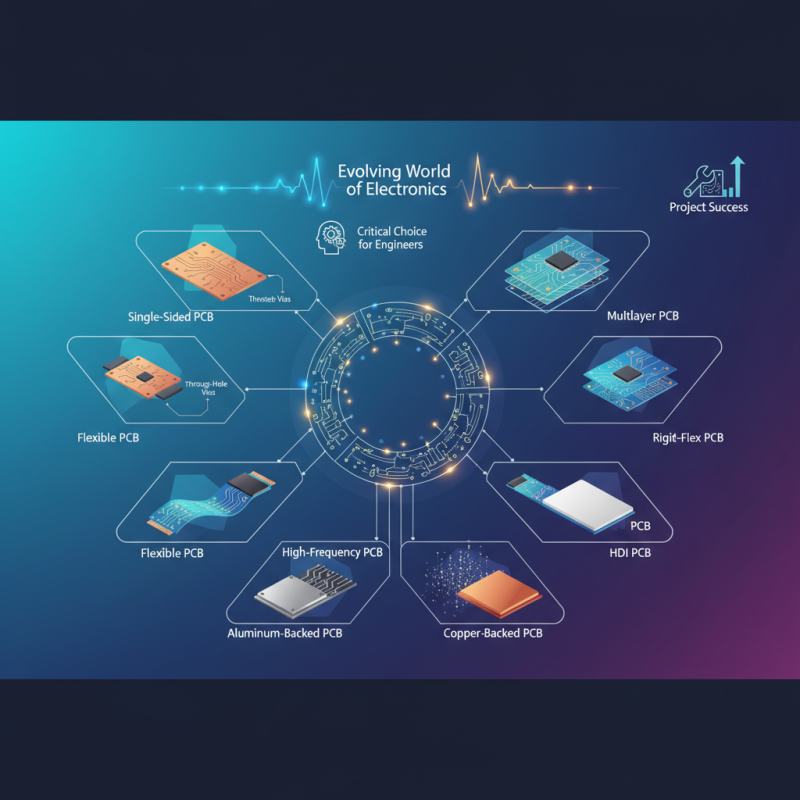

In the rapidly evolving world of electronics, the choice of the right PCB board can significantly impact the performance and success of a project. As industry expert Dr. Emily Martin, a renowned specialist in printed circuit board design, aptly states, "Selecting the right PCB board type is critical; it can be the difference between a robust product and a failing one." With an array of options available, each with unique characteristics and applications, understanding the distinct types of PCB boards is essential for engineers and designers.

This article delves into the top 10 PCB board types, discussing their features, advantages, and best-use scenarios. From single-sided to multilayer boards, the decision-making process can often be challenging, especially when considering factors such as cost, complexity, and functionality. By exploring the various options, we aim to guide you in making an informed choice that aligns perfectly with your project's requirements. Whether you're designing a simple electronic application or a complex system, the right PCB board is pivotal to your success.

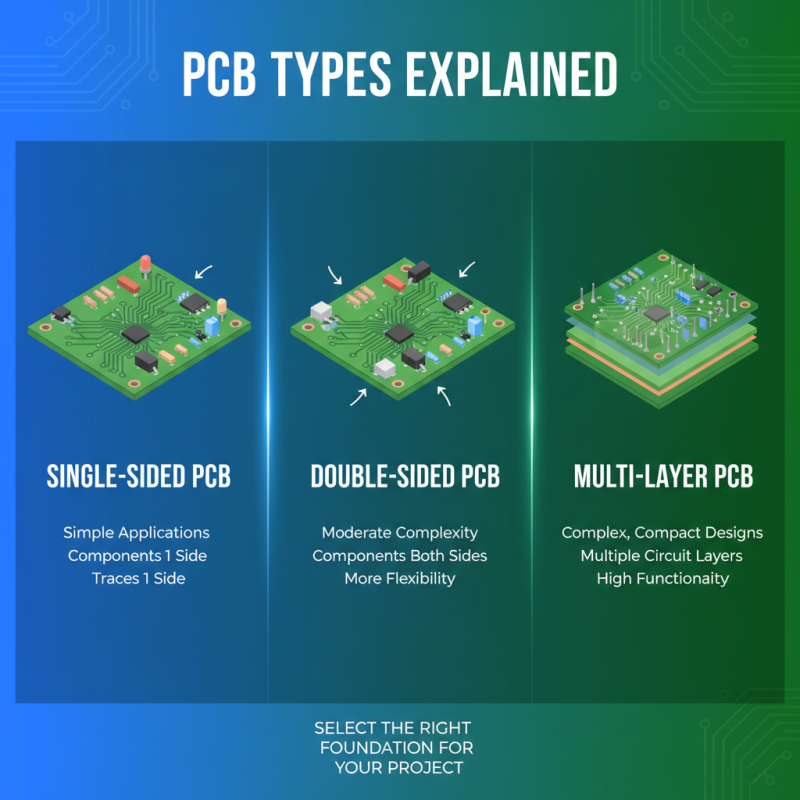

When it comes to printed circuit boards (PCBs), understanding the various types available is crucial for selecting the right one for any electronic project. PCBs are central to the functionality of electronic devices, serving as the foundation where components are mounted and interconnected. The most common types include single-sided, double-sided, and multi-layer PCBs. Single-sided boards have components on one side and traces on the other, making them ideal for simple applications. In contrast, double-sided PCBs allow for components on both sides, providing greater flexibility and density for more complex circuits. Multi-layer PCBs, involving several layers of circuitry, are designed for intricate projects requiring compact design and high functionality.

Another significant category of PCBs is flexible and rigid-flex boards, which offer unique advantages in specific applications. Flexible PCBs can bend and twist, making them suitable for devices with limited space or those requiring movement, such as wearable technology. Rigid-flex boards combine the benefits of both rigid and flexible designs, allowing for complex configurations in tight spaces. Additionally, there are specialized types, like high-frequency boards, which are optimized for RF applications, and metal-backed PCBs, known for their superior heat dissipation capabilities. Understanding these diverse PCB types is essential for effectively addressing the demands and specifications of any electronics project.

When selecting the right PCB board type for your project, understanding the material composition is crucial. Among the most prevalent substrates is FR-4, a glass-fiber-reinforced epoxy laminate that offers exceptional electrical insulation properties. It’s widely used because of its versatility, durability, and affordability, making it an ideal choice for many standard applications. FR-4 can handle a temperature range suitable for most electronic devices, ensuring reliability in standard operating conditions.

On the other end of the spectrum is Rogers material, which is prized for its high-frequency performance. Composed primarily of PTFE, Rogers substrates are designed for applications that require minimal signal loss and predictable dielectric properties. This makes them perfect for RF and microwave applications, where maintaining signal integrity is essential. Other materials like polyimide and aluminum-based boards are also used in specialized applications, offering unique benefits like flexibility or thermal management.

**Tip:** When selecting a substrate, consider not only the electrical performance but also the thermal characteristics and mechanical strength required for your specific application. This evaluation can help you avoid common pitfalls and ensure your PCB performs optimally in its intended environment.

**Tip:** Always assess the manufacturing capabilities for the materials you are considering. Certain substrates may require specialized processes or tools, which can influence both the cost and time frame of your project.

This chart displays the material cost per square foot for various PCB board types. Understanding these costs is crucial for selecting the right substrate for your project.

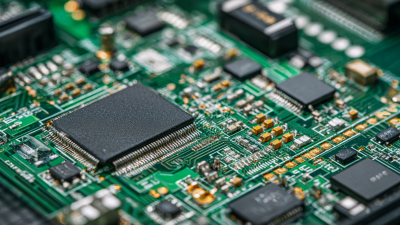

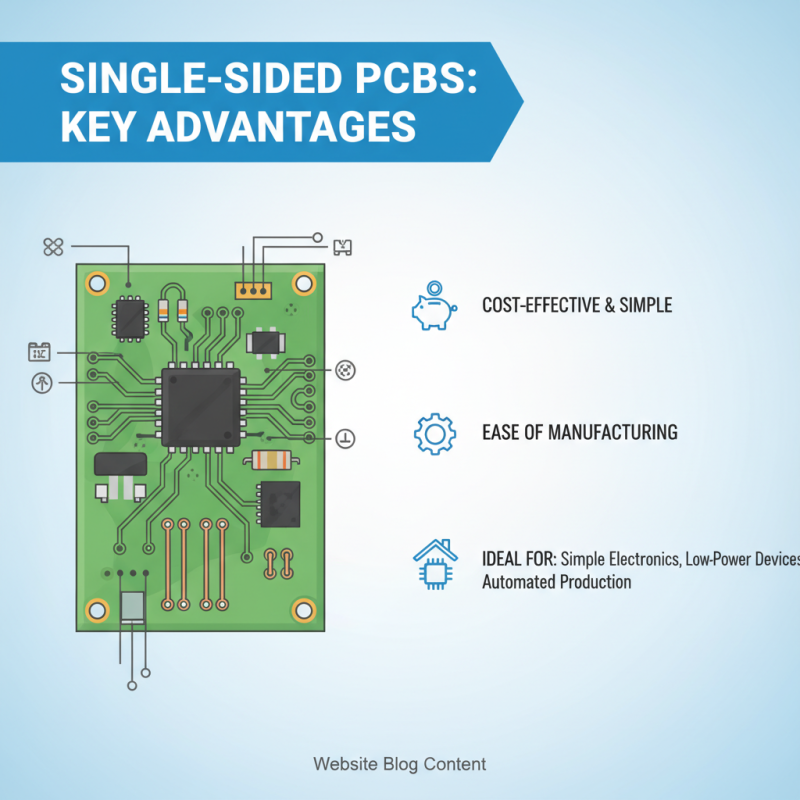

When it comes to designing printed circuit boards (PCBs), choosing between single-sided and double-sided options is fundamental to the overall success of a project. Single-sided PCBs feature components on only one side of the board, making them a cost-effective choice for simpler applications. Their straightforward design allows for ease of manufacturing and assembly, ideal for low-power devices, consumer electronics, and automated production processes. However, their limitations in terms of component density can restrict more complex designs.

On the other hand, double-sided PCBs offer greater flexibility and density, allowing for components to be placed on both sides of the board. This design approach is particularly beneficial for more intricate projects where space is at a premium. Double-sided PCBs can incorporate more functionalities and complex circuits, supporting high-performance applications in industries such as telecommunications, medical devices, and industrial machinery. With vias connecting the two sides, designers can create a compact layout that optimizes circuit paths and minimizes interference. Ultimately, the choice between single-sided and double-sided PCBs hinges on the specific requirements of the project, including complexity, cost, and performance expectations.

Multilayer PCBs are integral to the advancement of modern electronics, especially in the realm of complex circuit designs. These boards, typically comprising three or more conductive layers stacked together, offer significant advantages over single-sided or double-sided PCBs. For instance, a report by the IPC (Institute of Printed Circuits) indicates that multilayer PCBs provide improved signal integrity and reduced electromagnetic interference (EMI), crucial for high-frequency applications. As electronics continue to shrink in size while increasing in complexity, multilayer designs become an essential solution, enabling manufacturers to create compact devices that still maintain optimal performance.

Applications for multilayer PCBs are widespread, ranging from telecommunications to medical devices. In telecommunications, where data transfer rates are critical, multilayer PCBs facilitate the intricate routing of circuit paths needed for high-speed connections. According to industry analyses, the growth of 5G technology is projected to drive a 10% increase in multilayer PCB demand by 2024, highlighting their pivotal role in next-generation devices. Furthermore, in the medical sector, where precision and reliability are paramount, multilayer boards allow for advanced functionality in diagnostic equipment and life-saving devices, underscoring their value in critical applications. As technology trends evolve, multilayer PCBs will continue to shape the landscape of electronic circuit design, adapting to meet the needs of increasingly sophisticated applications.

Flex and rigid-flex printed circuit boards (PCBs) have emerged as innovative solutions for projects where space is at a premium. These types of PCBs combine flexibility and functionality, making them ideal for compact devices in various industries, including consumer electronics, medical devices, and aerospace.

Flex PCBs are predominantly made from thin, flexible materials that can be bent and shaped to fit into intricate designs, allowing for greater freedom in product development.

Rigid-flex PCBs, on the other hand, incorporate both rigid and flexible sections, offering the advantages of both types while maintaining structural integrity.

The technological advancements in flex and rigid-flex PCBs have led to significant improvements in performance and reliability. Designers can now create lighter and more compact products without sacrificing functionality, which is crucial in applications where weight and space constraints are critical. Additionally, these innovations help reduce the number of interconnections needed in a design, further minimizing the risk of mechanical failure or signal loss. Consequently, engineers can focus on creating more sophisticated electronic functionalities while ensuring that their designs meet the stringent requirements of modern applications.