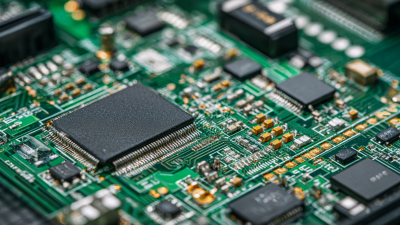

As the demand for innovative electronic devices continues to surge, the importance of prototype PCB manufacturing has never been greater. In 2025, the landscape of PCB manufacturing companies is poised to evolve significantly, driven by technological advancements and the need for rapid prototyping in various industries such as consumer electronics, automotive, and telecommunications. Understanding which companies excel in this field is crucial for businesses looking to stay ahead in a competitive market.

This article explores the top 10 prototype PCB manufacturing companies that you should keep an eye on in 2025. These companies have consistently demonstrated their capability to deliver high-quality prototyping services, alongside flexibility and reliability. From small startups to established industry leaders, each of these firms brings unique strengths to the table, contributing to the broader ecosystem of electronic manufacturing. Whether you are a startup in need of quick turnarounds or an established player seeking cutting-edge technology, knowing the top contenders in prototype PCB manufacturing will empower your decision-making and facilitate superior product development.

In 2025, the landscape of PCB prototyping is set to evolve dramatically, driven by several key trends. One of the most significant advancements is the integration of artificial intelligence (AI) in the design and manufacturing processes. AI enables designers to optimize layouts and materials more efficiently, resulting in quicker turnaround times and enhanced performance of printed circuit boards. Additionally, the use of flexible materials will gain prominence, allowing for more innovative applications in wearable technology and IoT devices.

Another vital trend is the rise of additive manufacturing, or 3D printing, in electronics. This technique will facilitate the creation of complex geometries and structures that traditional manufacturing methods can't achieve. Moreover, Lab-on-PCB technology, which merges biological systems with printed circuit boards, is poised to revolutionize medical diagnostics and monitoring. As the PCB assembly market is projected to grow significantly, companies that leverage these emerging technologies will be at the forefront, capitalizing on new opportunities within the electronics industry.

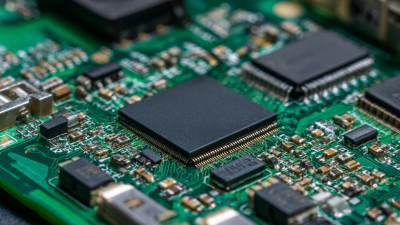

When selecting a PCB manufacturing company, it's crucial to focus on key features such as the types of plating solutions they offer. Manufacturers typically utilize various copper and plating solutions, including copper plating solutions, tin plating solutions, silver plating solutions, gold plating solutions, and nickel plating solutions. These different finishes provide specific advantages, such as enhancing conductivity and solderability, which are vital for the reliability and performance of electronic devices. For instance, gold plating is often favored in high-performance applications due to its excellent corrosion resistance and conductivity.

Moreover, understanding the applications covered by the PCB manufacturer is essential. Companies often cater to specific needs such as through-hole plating, bump plating, and other specialized processes, which are fundamental for ensuring the integrity of connections within a circuit board. As the global PCB market is anticipated to grow from $741.2 billion in 2025 to $1,134.9 billion by 2032, the demand for specialized solutions and high-quality manufacturing processes is on the rise. This growth can be attributed to the increasing integration of PCBs in automotive and AI technologies, which emphasizes the need for advanced PCB solutions that meet evolving industry standards.

When searching for the best PCB prototyping services, it is crucial to evaluate a number of key factors that can significantly influence the quality and efficiency of your projects. First and foremost, look for companies that offer a range of technologies and materials to cater to various design requirements. It is essential that these manufacturers are equipped with advanced machinery capable of handling both simple and complex designs, enabling rapid production turnaround times. The ability to support quick iterations can also enhance the prototyping process, allowing companies to accelerate their time to market.

Moreover, excellent customer support and communication are vital components of any PCB prototyping service. A reliable manufacturer should provide comprehensive consultation throughout the design and fabrication phases, ensuring that potential issues are addressed proactively. This level of engagement not only fosters a better understanding of project needs but also helps in building a strong partnership. Finally, consider the company’s reputation and reviews within the industry to gauge their reliability and quality, as these insights can lead you to the best options for your prototyping needs.

The impact of technological advancements on PCB manufacturing is profound and multifaceted. With the rise of automation and advanced manufacturing techniques, companies are now able to produce printed circuit boards with greater accuracy and efficiency. Innovations such as automated pick-and-place technology and computer-aided design (CAD) systems have streamlined the design and production process, minimizing human error and reducing lead times. Furthermore, advanced materials and processes, including flex-rigid circuits and high-density interconnect (HDI) technology, enable manufacturers to create smaller, lighter, and more complex designs that meet the demands of modern electronics.

Additionally, the shift towards Industry 4.0 has brought about significant changes in PCB manufacturing. The integration of the Internet of Things (IoT) and smart manufacturing technologies allows for real-time monitoring and data analytics, enhancing production efficiency and product quality. These advancements not only reduce waste and lower manufacturing costs but also improve the ability to customize PCBs for specific applications, responding rapidly to market changes. As a result, manufacturers adopting these technologies are better positioned to compete in a fast-paced industry, ensuring they remain at the forefront of innovation and quality in PCB production.

As the demand for printed circuit boards (PCBs) continues to rise, leading manufacturers are increasingly focusing on sustainability practices to minimize environmental impact. Recent studies indicate that approximately 70% of electronic waste comes from discarded PCs and consumer electronics, highlighting the necessity for eco-friendly manufacturing solutions. Companies are beginning to integrate advanced materials and innovative processes into their operations, aiming to reduce carbon emissions and waste associated with traditional PCB manufacturing methods. In particular, the adoption of eco-friendly materials is gaining traction, as businesses strive to comply with regulatory standards while also embracing genuine environmental responsibility.

One notable development in the industry is the use of digital twins, which allow manufacturers to simulate the production process and assess sustainability metrics in real-time. This innovation not only optimizes production efficiency but also facilitates a shift towards a circular economy by identifying areas where waste reduction can occur. Additionally, firms are exploring flexible PCB manufacturing techniques, striving for methods that balance performance with environmental stewardship. By leveraging novel technologies and a commitment to sustainable practices, PCB manufacturers are positioning themselves as leaders in the transition towards greener electronics, ultimately contributing to a more sustainable future for the industry.